Reflow soldering operation process specification

Release time:2024-02-01Publisher:Jeenoce

The process specifications for reflow soldering are as follows:

1. Operators must wear labor protection equipment, including fire-resistant welding suits, dust masks, anti slip shoes, etc.

2. Operators must receive relevant safety training, understand the risks and measures of welding operations.

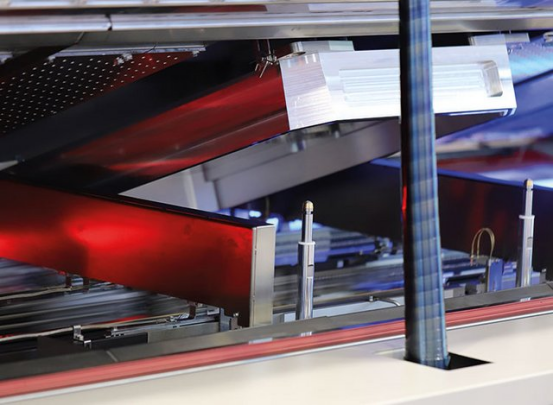

3. Before operation, it is necessary to check whether the equipment is normal. If there are any abnormalities, they should be reported for repair or replaced in a timely manner.

4. Operators should inspect the surrounding environment to ensure smooth safety channels and maintain good communication and collaboration with other operators.

5. Before operating the reflow welding machine, confirm that the required materials and workpieces are complete.

6. Before opening the reflow soldering machine, fire-resistant and scald proof items should be placed around the equipment and ensure good ventilation.

7. Operators need to adjust welding parameters (such as temperature, feeding speed, etc.) based on the size and requirements of the workpiece.

8. Place the workpiece on the welding table to ensure a tight fit between the workpiece and the welding interface.

9. Turn on the device power, select the appropriate welding program on the machine interface, confirm, and start welding.

10. During the welding process, operators need to constantly monitor the working status of the equipment to ensure that the welding process proceeds normally.

11. In case of unexpected situations, such as abnormal noises, smoking, etc., the operator should immediately stop the operation and notify relevant personnel to troubleshoot.

12. After welding is completed, turn off the power supply of the equipment and carry out relevant cleaning work. When cleaning, it is necessary to ensure that the equipment is in a power-off state.

Please note that the width of the reflow soldering machine guide rail should be adjusted according to the width of the PCB, by turning on the air transport, mesh belt transport, and cooling fan. The maximum temperature control for the reflux machine is (245 ± 5) ℃, and the temperature before PCB contact is between 80 ℃ and 110 ℃. Strictly control the computer parameter settings of the reflow welding machine according to the parameters provided by the welding production process, and record the reflow welding machine parameters on time every day.