How to reduce the lateral temperature difference of lead-free reflow soldering?

Release time:2024-01-31Publisher:Jeenoce

The temperature of lead-free reflow soldering is much higher than that of lead-free reflow soldering. It is difficult to adjust the temperature setting of lead-free reflow soldering, especially since the window of lead-free reflow soldering is very small. Therefore, controlling the transverse temperature difference is very important. The process window of lead-free reflow soldering is very small. If the transverse temperature difference between two points in the lead-free reflow soldering furnace is large, it will cause various adverse problems in the solder joints of lead circuit boards. Therefore, controlling the transverse temperature difference in the lead-free reflow soldering furnace is very important. How to reduce the lateral temperature difference of reflow soldering and achieve the ideal effect of reflow soldering, JEENOCE will share with you here.

1、 Hot air transportation for temperature zone reflow soldering

At present, the mainstream reflow soldering adopts the full hot air heating method. In the development process of reflow soldering, infrared heating has also emerged. However, due to heating, the infrared absorption and reflectance of devices of different colors are different, and the shadow effect generated by the shielding of adjacent components. The temperature difference can cause the welding wind to jump out of the process window. In the heating methods of reflow soldering, infrared heating technology is gradually being phased out. During the welding process, attention should be paid to the heat transfer effect, especially for the original high heat device. If the heat transfer is not sufficient, it will cause a significant acceleration of the temperature rise after the small heat capacity device, resulting in a lateral temperature difference.

2、 Speed control of lead-free reflow soldering chain

The chain speed control of lead-free reflow soldering will affect the lateral temperature difference of PCB. Generally speaking, reducing the chain speed will bring more heating time to large heat capacity equipment, thereby reducing the lateral temperature difference. However, the setting of the furnace temperature curve depends on the requirements of the solder paste. Therefore, it is not realistic to reduce the chain speed limit in actual production, which depends on the use of solder paste. If there are many heat absorbing components on the circuit board, it is recommended to reduce the speed of the reflow soldering transmission chain so that the larger chip components can fully absorb heat.

3、 Control of wind speed and air volume in lead-free reflow soldering

If other conditions for reflow soldering remain unchanged, the temperature on the circuit board will only decrease by about 10 ℃ when the reflow soldering fan speed is reduced by 30%. It can be seen that the control of wind speed and air volume is very important for the control of reflow soldering. In order to achieve control of wind speed and air volume, it is necessary to pay attention to two points of control, reduce the lateral temperature difference of reflow soldering, and improve the welding effect;

1. Adopting variable frequency speed regulation to reduce the impact of voltage fluctuations on the fan;

2. Try to minimize the exhaust volume of reflow soldering, as the central load of the exhaust volume is often unstable, which can easily affect the flow of hot air in the reflow soldering furnace.

4、 Good reflow soldering stability can reduce the temperature difference inside the furnace

Even if the reflow soldering setting is good, stability, repeatability, and consistency need to be ensured. Especially in production, due to equipment reasons, if there is a slight drift, it is easy to jump out of the process window, causing cold welding or equipment damage. Therefore, more and more manufacturers are paying attention to the stability of their equipment.

5、 The influence of lead-free reflow soldering structure

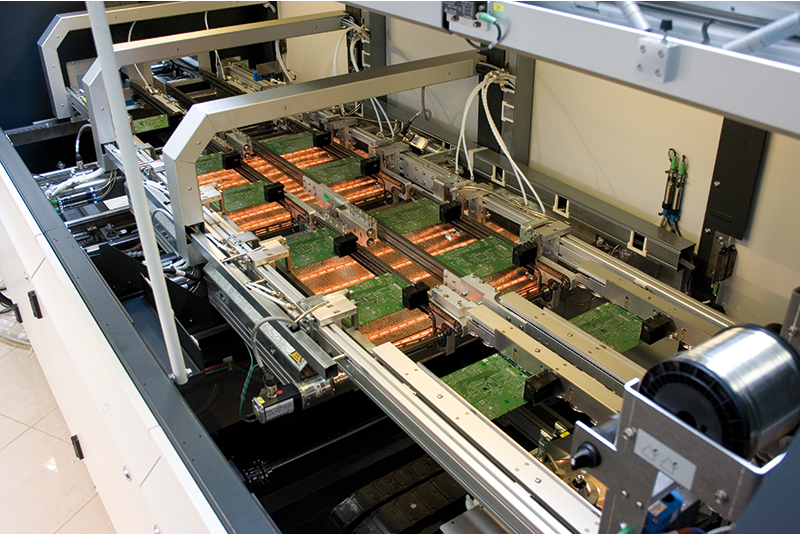

Lead free reflow soldering transfer method:

There are generally three types: guide rail type, mesh belt type, and guide rail+mesh belt type. The temperature near the end of the guide rail is generally lower, so the reflow soldering guide rail should be as far away from the return air outlet as possible, and it is not recommended to use the * * * width limit to weld the product. If it is a single panel, then the mesh belt or a single guide rail is more likely to achieve less lateral temperature difference.

Lead free reflow soldering duct structure:

Hot air ducts are generally divided into single ducts and double ducts. The ventilation structure of a single duct is relatively simple and easy to maintain, making it the mainstream method for mid to low end reflow soldering. However, for products that require high precision and high hot air efficiency, double duct reflow soldering is generally required. Such reflow soldering equipment has a relatively high manufacturing cost, so it is usually used for high-end reflow soldering.

6、 Stability of lead-free reflow soldering equipment

Even if we obtain a high furnace temperature curve setting, achieving it still requires equipment stability, repeatability, and consistency to be guaranteed. Especially in lead-free production, if there is slight drift due to equipment reasons, it is easy to jump out of the process window and cause cold soldering or damage to the original components. So, more and more manufacturers are beginning to demand stability testing for their equipment.