The advantage of industrial CT measurement is that it can achieve internal measurement of products

Release time:2024-01-25Publisher:Jeenoce

Industrial CT has become a versatile and comprehensive expert, playing an irreplaceable role in detecting defects such as internal pores and cracks in precision workpieces, diagnosing welding quality, detecting internal structures and assembly conditions, and providing an ideal data source for equipment manufacturing and industrial non-destructive testing.

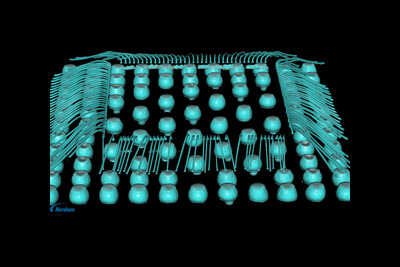

Industrial CT is different from traditional measurement methods such as coordinate detection and imager. It can accurately measure all scales of the workpiece without damaging the sample, with high accuracy and fast speed. By using industrial CT, it is possible to intuitively understand the two-dimensional and three-dimensional local overall, perspective, or cross-sectional analysis of the product, analyze and measure the installation gaps between components, evaluate technology, identify the cause of faults, address related issues, and reduce research and development investment costs.

Main functions of industrial CT:

1. Multiple detection methods are adopted, including cone beam CT scanning and DR real-time imaging. Based on the size of the detected workpiece, a single scan can obtain fault images from dozens to thousands of layers.

2. The radiation source and imager configured in the system can be flexibly selected.

3. Capable of defect and pore analysis, as well as defining the area of the inspected workpiece.

4. Identify the volume, location, and size of defects using different colors.

5. Analyze wall thickness: Identify the analysis results with different colors.

6. Measurement tools: measure parameters such as workpiece position, distance, radius, angle, etc.

7. Reverse engineering: CAD design and physical comparison.

8. Segmentation tool: A dataset that is segmented based on materials and geometric structures.

9. It can achieve precise measurement of the internal dimensions of the inspected workpiece.

In summary, industrial CT is a widely used detection tool with many important functions that other non-destructive testing methods do not possess. In foreign countries, industrial CT is not only applied to the detection of important products such as aerospace, pyrotechnic products, precision machinery, but also in many fields such as automobiles, petroleum, geology, archaeology, wood, etc. In recent years, its application and development in China have also been rapid.