Industrial CT has many advantages over traditional detection methods

Release time:2024-01-18Publisher:Jeenoce

The measurement technology of industrial CT scan is based on the new measurement principle. Industrial CT is widely used in the field of non-destructive testing and material composition inspection. With the increasing demand for accurate measurement of the internal and external geometric characteristics of the system, industrial CT has added dimensional metrology application characteristics. Industrial CT scanning measurement technology has become an important application field of industrial CT technology. Compared with other measuring instruments such as CMM, it has many advantages.

Industrial CT uses accurate positioning, and the image is easier to recognize. Conventional X-ray detection technology mainly projects three-dimensional objects onto two-dimensional planes, which is easy to cause the superposition of image information. If you want to obtain the information on the image, it is very difficult to accurately locate and quantitatively measure the target without experience. When detecting the workpiece, industrial CT can give 2D or 3D images, and the target to be measured will not be blocked by the surrounding details, and the obtained image is very easy to identify. The specific spatial position, shape and size information of the target feature can be obtained directly from the image.

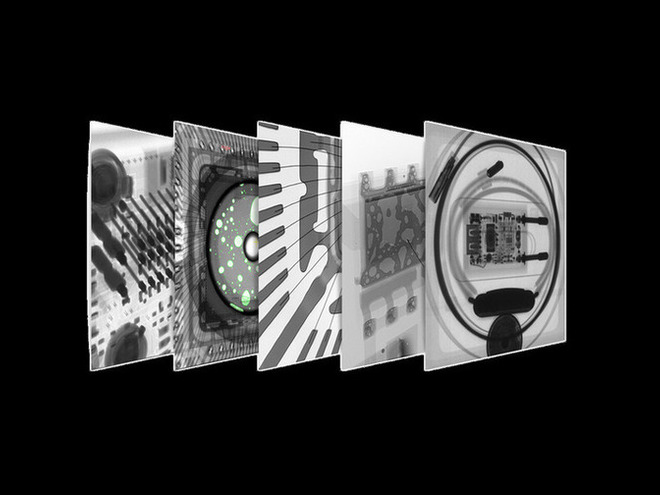

The basic principle of industrial CT is based on the attenuation and absorption properties of radiation in the detected object. It is related to the absorption capacity of a substance to radiation and its properties. Therefore, the use of radionuclides or other radiation sources emitted, with a certain energy and intensity of X-ray or gamma rays, in the detected object attenuation law and distribution, it is possible to obtain the detailed information inside the object by the detector display, and then use computer information processing and image reconstruction technology to display in the form of images.

Industrial CT system Main functions:

1. With the cooperation of the tooling, DR Imaging and CT tomography detection can be realized on any part of the workpiece;

2. Realize industrial CT detection of cracks, pores and inclusions of the inspected workpiece, and use measurement methods to complete the measurement of cracks, pores and inclusions;

3. With basic image processing and measurement functions, the corresponding functions can be expanded according to user needs;

4. Basic functions of image processing: Cutting position display and positioning, 3D imaging, reverse CAD, local scanning, linearization correction processing, filtering, image reverse color, false color processing, image enhancement processing, image smoothing processing, image equalization processing, window width and window position adjustment, image format conversion, image overall scaling, local scaling, fault self-diagnosis and prompt, High frequency information image reconstruction, system imaging software parameter backup, image database function, etc.

5. Image editing and measurement functions: relative density measurement, size measurement (any two point length measurement, curve arc length measurement, radius measurement), equal density distribution area and volume statistics, gray statistics in any area, data statistics (average density measurement in any area, etc.).