Pay attention to the use of liquid dispensing

Release time:2024-01-18Publisher:Jeenoce

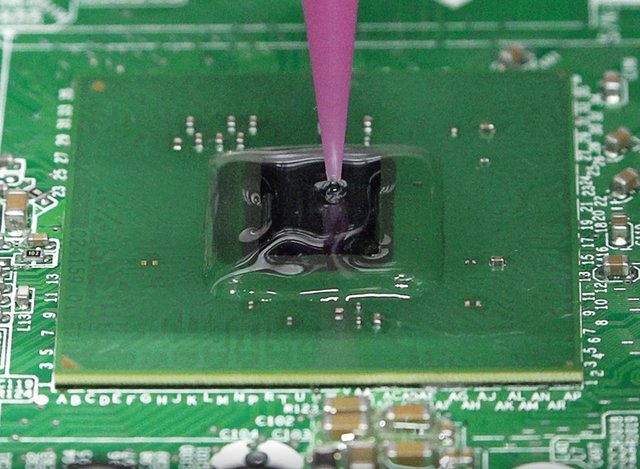

First of all, the size of the dispensing amount is usually considered that the size of the dot diameter should be half of the product spacing, so as to ensure that there is enough glue to bond the component and avoid too much glue. The amount of glue is determined by the length of time, and the actual dispensing time should be selected according to the temperature and the characteristics of the glue. Secondly, in terms of dispensing pressure, usually too much pressure can easily cause glue overflow and too much glue; If the pressure is too small, there will be intermittent dispensing phenomenon and leakage points, resulting in product defects, so it needs to be adjusted according to factors such as ambient temperature and glue viscosity. In addition, the needle of the dispensing machine usually selects a needle whose inner diameter is about 1/2 of the diameter of the dispensing point, and the dispensing needle should be selected according to the size of the product during the dispensing process. There is also the distance between the needle and the working face, different dispensers use different needles, some needles have a certain degree of stop, so it is necessary to grasp the dispensing distance, even before each work should be done to calibrate the distance between the needle and the working face, that is, Z-axis height calibration.

In addition to the factors of the dispensing machine itself, the viscosity of the glue directly affects the quality of the dispensing, the viscosity is large, the glue point will become smaller, and even drawing; The viscosity is small, the glue point will become larger, and then may permeate the product, and the glue temperature should be 23℃ ~ 25℃; The influence of ambient temperature on the viscosity of glue, the decrease of temperature and the increase of viscosity, the corresponding decrease of glue flow, and the phenomenon of wire drawing is more likely. The glue curing temperature curve has been given by the manufacturer, in practice, the higher temperature should be used as far as possible to cure, so that the glue has sufficient strength after curing.

In addition, the glue must not have bubbles. A small bubble will cause many products without glue; When replacing the hose midway each time, the air at the connection should be emptied to prevent the phenomenon of empty beating.