Industrial CT: Key Technology for Aerospace Testing Transformation

Release time:2024-01-12Publisher:Jeenoce

The development level of the aerospace industry is of great significance to a country, as it involves multiple aspects such as national security, economic development, technological innovation, education and training, and international influence. Therefore, countries around the world attach great importance to the development of the aerospace industry and invest a lot of resources and energy to promote progress in this field.

Since the 1950s, China's aerospace industry has made significant progress in over half a century and has become one of the world's leading aerospace powers.

Correspondingly, detection technology also needs to keep up with the times. Many new requirements that are difficult to meet in traditional detection technologies, such as high precision, high efficiency, multifunctionality, automation, non-destructive and traceability, call for the upgrading and replacement of detection methods in the aerospace industry.

In the 1960s, CT technology was first applied in the medical field for non-invasive examination of the human body, and then gradually applied in the industrial field. It can be said that it is still a very young technology. However, its application in the aerospace field began as early as the 1980s, mainly for defect detection of engine internal structures.

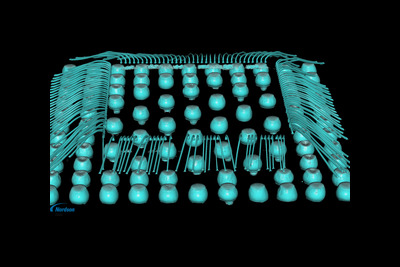

Nowadays, industrial CT has been hailed as the best non-destructive testing, non-destructive measurement, and failure analysis technology today. The basic principle is to use the characteristic of X-rays penetrating objects to scan the detected object, and display the internal structure, composition, and material defects of the detected object in a clear, accurate, and intuitive manner in the form of three-dimensional images.

The five major advantages of industrial CT, including non-destructive, high-precision, visualization, efficiency, and customizability, mean cost reduction, the possibility of digital production, and a significant leap in production efficiency and product quality for manufacturers. Therefore, industrial CT technology has also become a prominent "star of the future" in the testing industry in recent years.