How to quickly disassemble the screw pump used in the dispensing machine

Release time:2024-01-12Publisher:Jeenoce

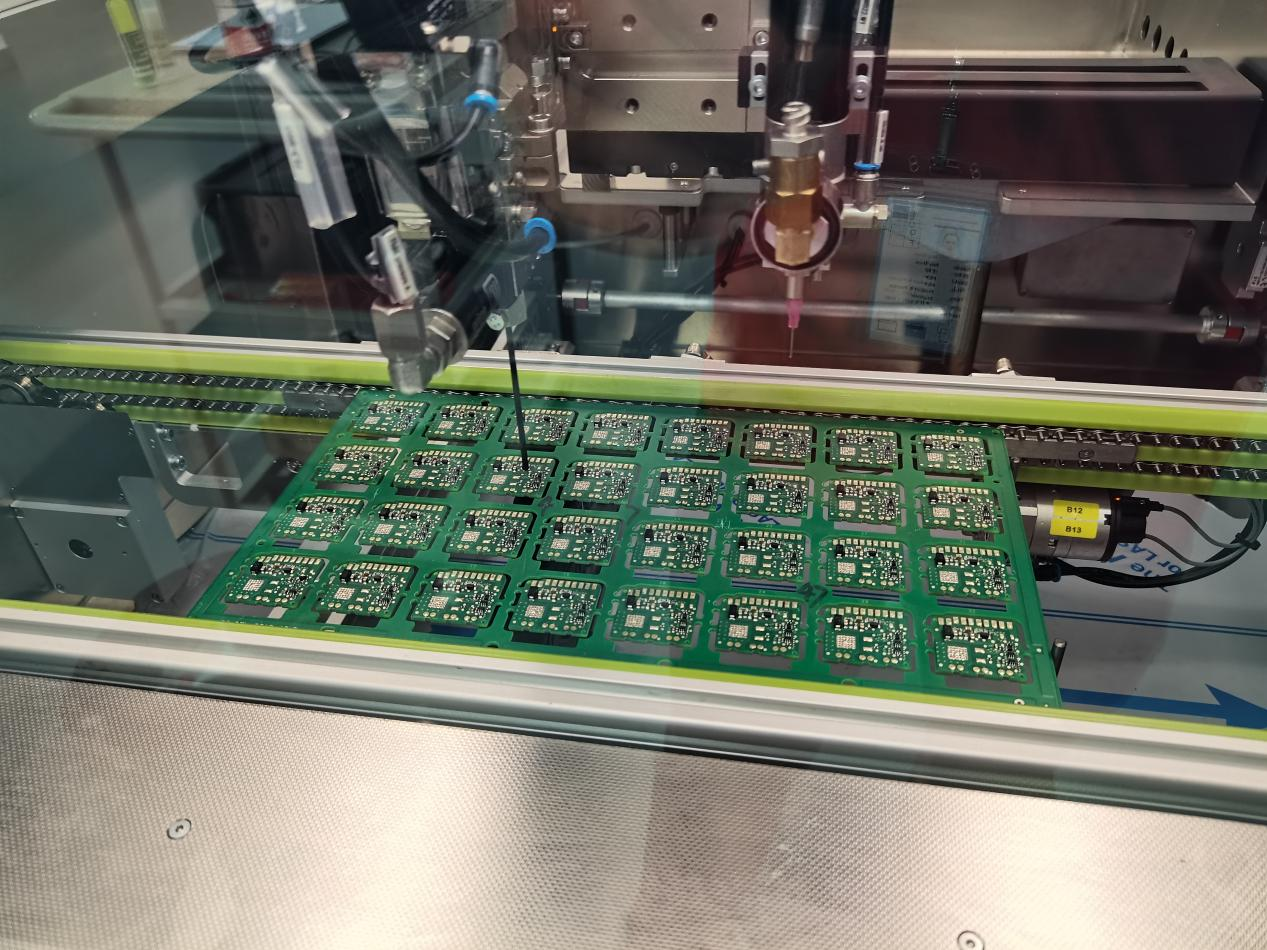

Die Schneckenpumpe der Dosiermaschine ist ein wichtiger Bestandteil der Dosiermaschine. Ihre Funktion besteht darin, den Kleber aus dem Leimgehälter zu extrahieren und den Kleber durch die Drehung der Schraube in die Dosierdüse zu drücken, um eine genaue Dosierung des Werkstücks zu erreichen. Aufgrund des häufigen Bedarfs an Reinigung und Wartung von Schneckenpumpen ist es sehr wichtig zu verstehen, wie man die Schneckenpumpe der Dosiermaschine demontiert. Hier sind einige Schritte, um die Schneckenpumpe der Dosiermaschine zu demontieren.

Prepare tools and materials

Disassembling the screw pump of the dispensing machine requires some basic tools, such as a wrench, wrench set, ring wrench, hammer, etc. In addition, some cleaning tools and liquids are needed, such as cotton cloth, petroleum ether, ethanol, etc. Before disassembly, please ensure that all necessary tools and materials are ready.

Turn off the power supply of the dispensing machine

Before disassembling the screw pump of the dispensing machine, it is necessary to turn off the power of the dispensing machine to prevent any unexpected situations.

Removing the screw pump

Firstly, it is necessary to remove the screw pump, usually using a wrench and a ring wrench. Before removing, it is necessary to first disconnect the inlet and outlet joints of the screw pump, and at the same time, remove the pump support bracket. Please be careful not to lose any small parts during disassembly.

Cleaning screw pump

After removing the screw pump, it needs to be cleaned. Firstly, clean the surface of the pump with a cotton cloth. Then, disassemble the screw pump and clean the screw, pump body, front and rear covers and other components separately. Cleaning liquids such as petroleum ether or ethanol can be used. When cleaning, it is necessary to carefully inspect each component for damage or wear.

Replace seals and lubricating oil

If the seal of the screw pump is found to be damaged or worn, it needs to be replaced. In addition, after cleaning the screw pump, it is necessary to add lubricating oil again and ensure that the oil is within the specified horizontal line.

Installing screw pump

After cleaning and replacing necessary components, the screw pump needs to be reinstalled back into the dispensing machine. When installing, it is necessary to follow the reverse order of disassembly. Firstly, install the pump support bracket back into the dispensing machine and connect the joints of the inlet and outlet ports. Then, install the front and rear covers and screws of the screw pump back into the pump body. During installation, please ensure that each component is positioned correctly and operate according to the assembly diagram of the screw pump. Finally, tighten the fixing screws of the screw pump and check if they are securely fixed.

Conduct testing

After installation, testing is required to ensure that the screw pump can function properly. Firstly, it is necessary to add glue to the glue storage tank and turn on the power of the dispensing machine. Then, perform an air run test, push the glue out of the screw pump and spray it through the dispensing nozzle to check if it is working properly. If the test results are abnormal, it is necessary to check if any parts are installed incorrectly or need to be readjusted.

In short, dismantling the screw pump of the dispensing machine requires great caution and attention, as each component is very important. Before disassembly, all necessary tools and materials should be prepared and operated according to the above steps. If you are unsure how to disassemble or need more assistance, it is recommended to consult a professional glue dispensing machine maintenance personnel.