What are the advantages of using industrial CT for detection?

Release time:2024-01-04Publisher:Jeenoce

The X-ray inspection scheme can visually display the size and shape of defects inside the workpiece, making it easy to determine the nature of defects. As the original record of inspection, the X-ray film is studied from multiple sources and stored for a long time, which has high sensitivity for non-destructive testing of thin-walled parts. A defect image that is sensitive to body shape defects, has a true planar distribution, and accurate dimensions. In the quality inspection of pressure vessel welding, there is no strict requirement for surface smoothness, and grain size has little impact on the inspection results. It can be used for internal defect detection of various materials, so it is widely used in the quality inspection of pressure vessel welding.

The industrial CT scheme also has its obvious advantages:

Firstly, industrial CT technology obtains high-resolution tomographic images of the tested object, and the detection of industrial CT is not limited by the geometric structure of the tested object;

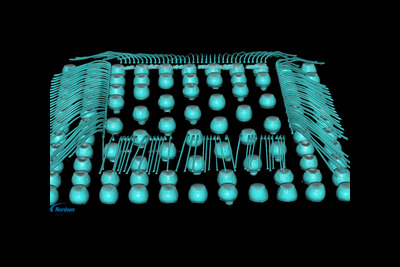

Secondly, industrial CT can not only display two-dimensional images of the tested sample, but also perform three-dimensional reconstruction of two-dimensional cross-sectional images on the workpiece, which can intuitively distinguish whether there are defects in the internal structure, material, and section of the tested object, as well as the shape, size, and position of internal defects in the workpiece. Moreover, the target information inside the workpiece is clear and will not be obscured by other interferences;

Thirdly, industrial CT technology has high spatial and density resolution, wide adaptability, and can be used for detection at different grayscale levels;

Fourthly, industrial CT images are easy to recognize and understand, and the detection results are more accurate.