The role of visual dispensing machines in the development of industrial dispensing technology

Release time:2024-01-04Publisher:Jeenoce

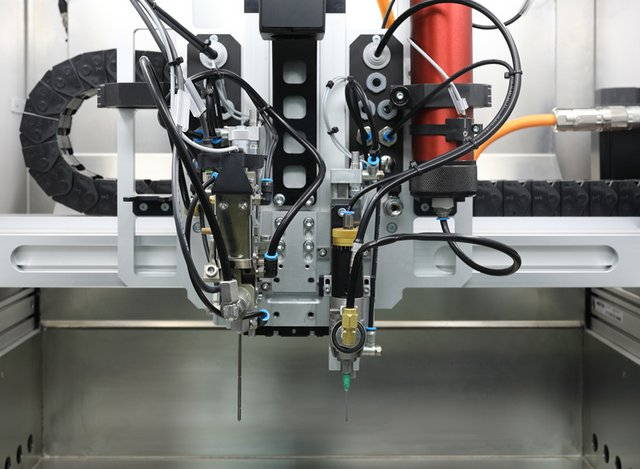

With the continuous improvement of industrial technology requirements, ordinary automatic dispensing machines are gradually unable to meet industrial needs. At this time, visual dispensing machines are gradually entering the view of manufacturers. With their high precision and fast dispensing effects, people are gradually accepting this emerging equipment, which can meet the needs of industrial technology.

Visual dispensing characteristics

Change traditional manual inspection to visual inspection function, replacing manual inspection of product quality and fixed-point effect. 2. For some high-precision glue dispensing products, there is still a slight error every time mechanical positioning is used. However, high-definition cameras can maintain alignment with the glue dispensing position, and effect processing only takes 1 second. Taking photos, data processing, analysis, fixed-point, and several steps can be completed within 1 second. 3. The degree of automation is becoming higher, Gluing can be done without the need for manual labor. Employees do not need to place the products properly, they can be placed directly for dispensing, and the quality of the products can be screened for compliance.

The jewelry industry often uses visual glue dispensers. Due to their affordable prices, they require mass production to be valuable. Ordinary glue dispensers can produce around 500-1000 units per hour, while visual glue dispensers can meet 5000 production needs at a very fast speed. Using crystal glue, the expected effect can reach 40K/H (dot). Subtracting the time it takes to pick up and place products, it can be seen that the effect is very fast. The visual dispensing machine also has a storage function, and the fixed dispensing position is recognized at this position every time.

In addition to being used in the jewelry industry, sign spray painting is also used for mahjong, car logos, signs, and other products that require quick dispensing. The cost model has basically changed, with fast production speed and good product quality, achieving the best of both worlds. Not only does it have production speed, but quality is also guaranteed. The visual dispensing machine can change the dispensing device. For example, for sign spray painting, a spray dispensing valve is used, which is fast, easy to control, and has strong sealing.