What are the advantages of industrial CT non-destructive testing?

Release time:2024-01-03Publisher:Jeenoce

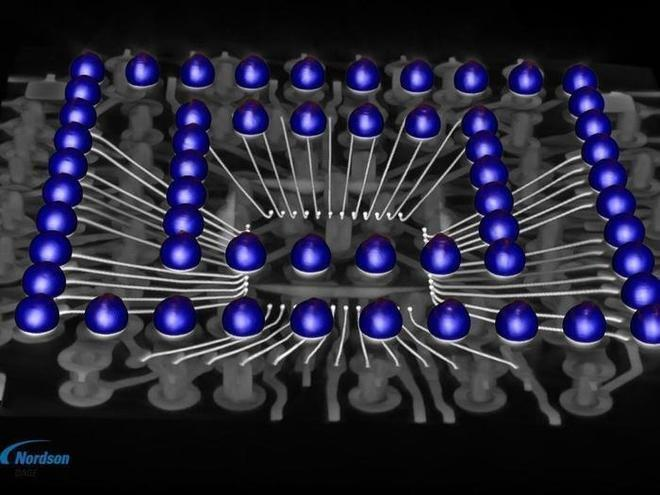

What are the advantages of industrial CT non-destructive testing? The basic principle of industrial CT non-destructive testing is based on the special effect of radiation being weakened and absorbed in the object being tested, which is related to the absorption ability and properties of the substance to radiation. Therefore, using X-rays with certain energy and intensity emitted from radioactive isotopes or other radiation sources γ Radiation, based on the pattern and distribution of weight attenuation of the object being measured, may be able to detect detailed information inside the object, which can then be displayed in the form of images through computer processing and image reconstruction techniques.

The advantages of industrial CT non-destructive testing include:

1. Density resolution ability

Industrial CT non-destructive testing has higher density resolution and outstanding density resolution. High quality CT images can even achieve a density resolution of 0.3%, which is at least an order of magnitude higher than conventional non-destructive testing techniques.

2. Dynamic corresponding range

The trend response range of industrial CT non-destructive testing is high. By using high-performance detectors, the dynamic response range of the detector can reach 106 or more, far higher than that of film and image intensifiers.

3. Positioning and Image Recognition

Conventional radiographic testing techniques can easily cause overlapping of image information. Without experience, it is very difficult to accurately locate and quantitatively measure targets in order to obtain information. When industrial CT non-destructive testing is used for measurement, it can provide clearer images, and the target to be measured will not be obstructed by other detailed features, making the image very easy to recognize. The specific spatial position, shape, and size information of the target can be intuitively obtained from images.

4. Image storage, transmission, and analysis

The images obtained from industrial CT non-destructive testing are intuitive, and the grayscale of the images is relative to the material, structure, composition, and density characteristics of the workpiece. Not only can the shape, position, and size of defects be obtained, but also the properties of defects can be determined by combining density analysis technology. This provides a more direct solution to the long-standing problem of defect spatial positioning, comprehensive qualitative, and depth quantitative that has plagued non-destructive testing personnel.