What are the types of splitters on the market and their advantages and disadvantages?

Release time:2024-01-02Publisher:Jeenoce

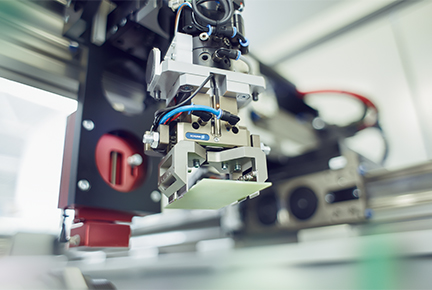

A PCB splitter usually refers to a PCB splitter, also known as a circuit board splitter.

Splitting machines are widely used in the electronic product manufacturing industry. Due to the strong stress generated by traditional manual folding methods, which have a serious impact on product quality, manual folding has been basically replaced by machine splitting.

Splitting machines can be divided into the following types:

1. Knife type splitter,

2. Stamping type splitting machine,

3. Milling cutter type splitting machine,

4. Laser Splitting Machine,

5. Knife type splitter.

The advantages and disadvantages of the above four types of splitters:

1. Advantages of the knife type slitting machine: low cost. Disadvantages: it can only perform linear slitting. There are rough edges.

2. Advantages of Stamping Splitting Machine: Low initial investment cost and fast speed. Disadvantage: Due to the need for specialized boards and molds, the later cost is high. Under stress

3. Advantages of the milling cutter type plate splitter: It can divide plates of any shape, with low stress and no burrs on the cutting edges. Disadvantage: The initial cost is relatively high.

4. Advantages of Laser Splitting Machine: It also has the advantages of a milling cutter type splitting machine and can perform differential cutting on PCB boards without stress. Disadvantage: The machine is expensive.

5. Advantages of the guillotine type divider: pure pneumatic (factory commonly used air pressure is sufficient), compact size (desktop type), high output, can cut aluminum substrates of any width and thickness, and has high cost-effectiveness