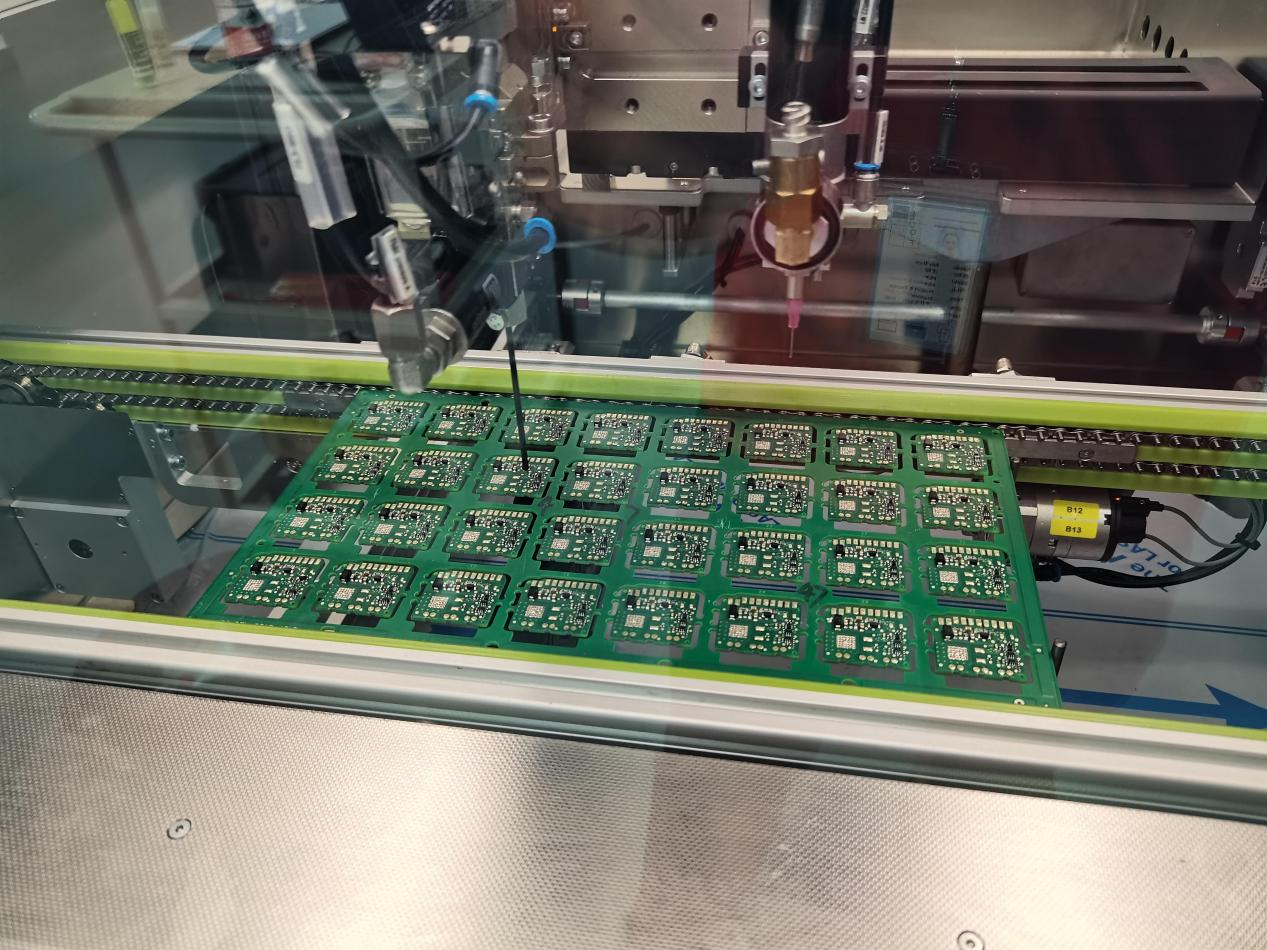

How to use the coating machine reasonably and effectively?

Release time:2024-01-02Publisher:Jeenoce

The optimal working state of the three proof glue coating machine can be adjusted from several aspects such as the needle selection, glue dispensing time, and dispensing pressure of the three proof paint coating machine.

1. Selection of coating machine needles:

The diameter inside the coating machine needle should be chosen to be the same as the radius of the adhesive point. In dispensing work, suitable dispensing needles can be selected based on the size of the product, and suitable needles should be selected for products of different sizes. In this way, there can be a three proof glue coating machine for dispensing work, avoiding the problem of defective glue points.

The minimum dispensing amount of the coating machine is 0.005 milliliters less than the standard amount. The minimum inner diameter of the stainless steel needle is 0.1 millimeters, and the minimum inner diameter of the needle is 0.1 millimeters. The coating machine has a specially designed needle with an inner diameter of up to 0.02 millimeters.

Attention: The height of the dispensing needle to the circuit board and the inner diameter of the needle are the most important parameters, so choosing the appropriate dispensing needle is also important.

2. Setting the dispensing time of the coating machine:

The setting of the dispensing amount should be half of the product spacing, ensuring sufficient dispensing amount to stick the components, and also paying attention to excessive glue leakage.

The dispensing amount of the coating machine can be adjusted by the dispensing time of the dispensing machine. In actual production, the dispensing amount and dispensing time can be adjusted according to specific conditions (workshop temperature, adhesive viscosity, dispensing speed, etc.).

3. Pressure setting of coating machine:

The amount of glue produced by the coating machine is determined by the pressure provided by the three proof glue coating machine controller to the rubber tube and needle. The pressure of the three proof paint coating machine determines the amount of glue produced and the speed of dispensing.

Excessive pressure can easily lead to problems such as glue spraying and excessive amount of glue, which can affect the appearance and aesthetics of the product; If the pressure is too weak, uneven dispensing and leakage of glue may occur, thereby affecting product quality issues.

In practical production, pressure should be set according to specific environments, such as adhesive viscosity, production workshop environment, and high or low temperature.