The Important Value of Vacuum Welding Technology

Release time:2023-12-28Publisher:Jeenoce

Welding is a common method of connecting different metal components. The welding rod is melted at a high temperature at the welding site, and after the welding rod cools and solidifies, different workpieces will be bonded together. However, under normal welding conditions, there are often many situations where welding residues overflow, which can have a serious impact on the quality of many high-end equipment and precision electronic products. Therefore, vacuum welding, which can effectively solve these problems, has emerged. So what important value will vacuum welding with excellent welding quality bring to modern industrial welding?

1、 The value of improving welding quality

Before the emergence of trustworthy vacuum welding, it was not possible to directly use welding for fixation in the production of many high-end equipment. Manufacturers often had to go through a lot of effort and choose other expensive methods to solve such problems, which not only cost a lot but also had unsatisfactory results. The emergence of vacuum welding has solved such problems in one fell swoop, and the direct improvement of welding quality has also led to a significant decrease in production costs.

2、 The value of improving product quality

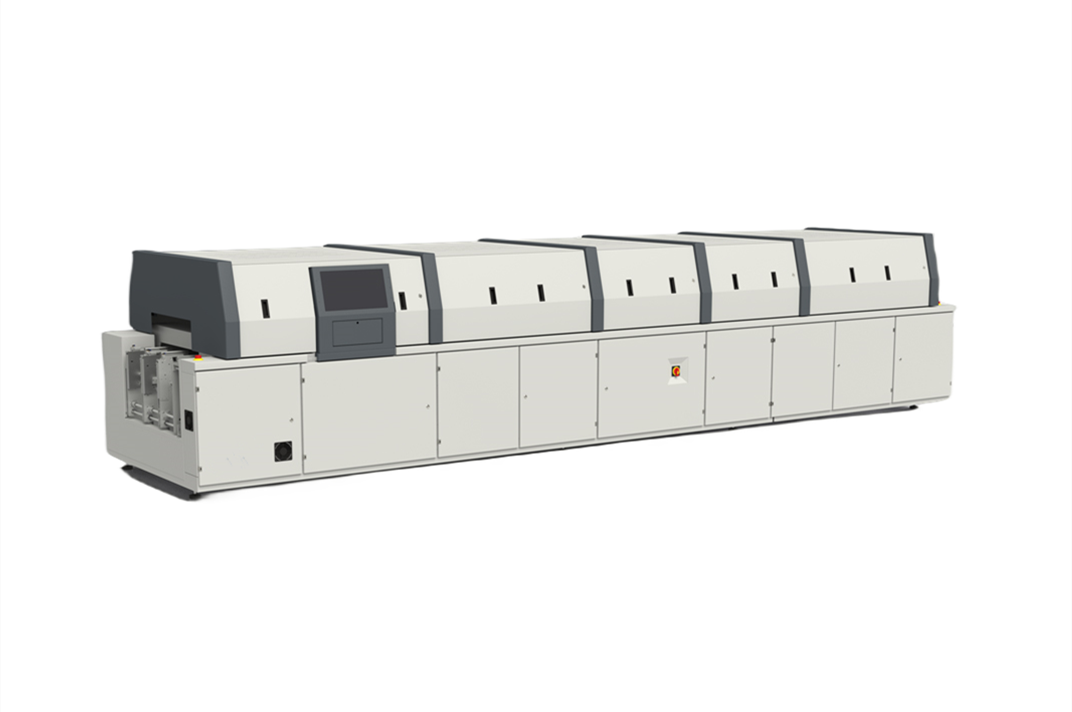

High quality vacuum welding can effectively reduce the occurrence of a large number of bubbles near the welding point under normal welding conditions after welding is completed, and also avoid oxidation problems near the welding point during welding. After using vacuum welding equipment, the quality of the product has been greatly improved by eliminating the two major welding difficulties mentioned above, bringing feasible welding solutions for the production of various high-end electronic products in the future.

3、 The value of strong product competitiveness

The main competitors of modern mainland electronic product manufacturers come from developed overseas countries, but the unstable quality of mainland electronic products often leads to high-end equipment and precision electronic products being sold at low prices in order to maintain competitiveness with overseas products in the market. The emergence of vacuum welding has significantly reduced the production cost of such products, and at the same time, the quality of products has also improved, indirectly enhancing the international competitiveness of domestic products.

Vacuum welding is a powerful improvement to modern industrial welding, and this welding mode can greatly enhance the production capacity of enterprises in high-end equipment. The emergence of vacuum welding has not only directly improved the welding quality of products, but also made progress in the quality and quality of high-end electronic products. In addition, this high-end welding technology has also enhanced the product competitiveness of mainland enterprises.