What are the functions of each component of reflow soldering equipment?

Release time:2023-12-27Publisher:Jeenoce

The functions of each component of the reflow soldering equipment are as follows:

1. Heating system: The heating system is the core part of the reflow soldering equipment, mainly consisting of preheaters, heaters, and coolers. Among them, the preheater is used to preheat the PCB board to a certain temperature to reduce heating time and heat loss during welding; The heater heats the solder paste and flux to a certain temperature, so that they can be evenly applied to the surface of the solder joint; The cooler is used to cool the PCB board to a stable temperature.

2. Peak system: The peak system is a device used to control the application of solder paste and flux on the surface of solder joints, usually composed of a peak pump, peak probe, and peak control circuit. The peak probe is used to connect the peak control system to the PCB board, in order to control the height and shape of the peaks; The peak pump is used to generate and control the pressure and flow rate of the peak; The peak control circuit is responsible for controlling the generation and adjustment of peaks.

3. Control system: The control system is used to control the entire process of reflow soldering equipment, including heating, peak, cooling, and other operations. It usually consists of electronic controllers, sensors, display screens, and communication interfaces.

4. Cooling system: The cooling system is used to cool the PCB board to a stable temperature. Usually including air cooling systems and water cooling systems.

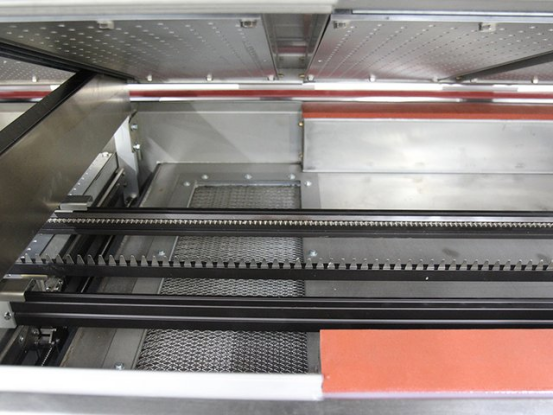

5. Conveyor system: The conveyor system is used to transport PCB boards to reflow soldering equipment for welding, usually composed of conveyor belts, electric rollers, and electromagnets.