Key points of reflow soldering process flow

Release time:2023-12-25Publisher:Jeenoce

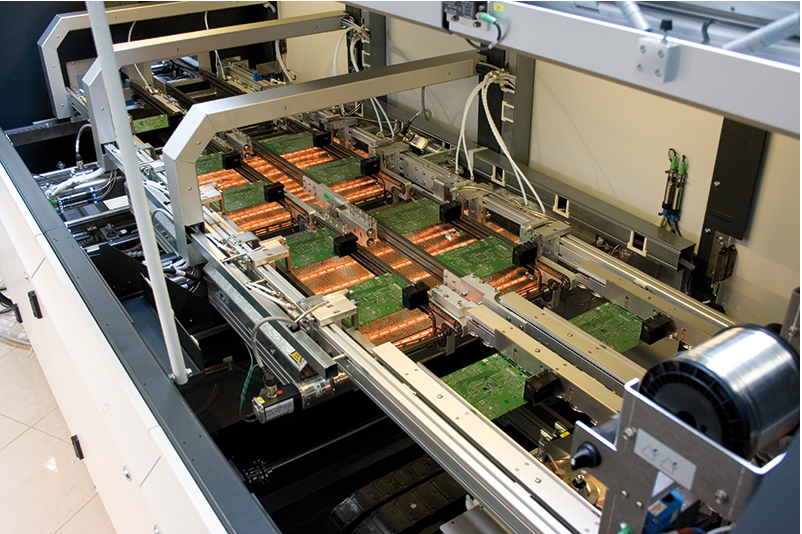

Reflow soldering is a widely used soldering technique in electronic manufacturing, mainly used for soldering or re soldering components onto circuit boards. Below, we will provide a detailed introduction to the key points of the reflow soldering process.

1. Preparation work

Before starting the reflow soldering process, sufficient preparation work needs to be done. This includes checking whether the equipment is functioning properly, ensuring that the furnace temperature is set within the correct range, and preparing the necessary materials (such as circuit boards, components, and solder paste). In addition, it is necessary to check the environmental conditions, such as temperature and humidity, to ensure compliance with process requirements.

2. Applying solder paste

Solder paste is a key component of reflow soldering process, which is a paste like substance composed of alloy powder and flux. The function of flux is to soften the alloy powder in the solder paste, allowing it to adhere to the circuit board, while also removing impurities and gases during the heating process. When applying solder paste, it should be ensured that it is evenly distributed to avoid blank areas.

3. Preheating

Preheating is a crucial step in reflow soldering technology. By heating, the flux in the solder paste evaporates, causing the alloy powder to interact with the surface active agent on the circuit board, preparing for welding. The preheating temperature and time should be adjusted according to the nature of the solder paste and the type of circuit board.

4. Welding

After reaching the welding temperature, the furnace transfers the circuit board to the welding area, causing the alloy powder to melt and combine with the surfactant on the circuit board. This process requires precise control of temperature and time to ensure welding quality. Once the welding is completed, the furnace will transfer the cooled circuit board out.

5. Inspection and repair

After welding is completed, it is necessary to check the welding quality and quantity of components on the circuit board. If any problems are found, they should be repaired immediately. During the repair process, ensure that the pins of the components are fully inserted into the holes on the circuit board and aligned correctly. Meanwhile, appropriate tools and methods should be selected for repair based on the type of circuit board and the size of components.

6. Cooling and packaging

After completing the repair, the circuit board should be cooled to room temperature and appropriately packaged to protect it from contamination and damage. Finally, production data and results should be recorded for quality analysis and improvement.

Reflow soldering is an important electronic manufacturing technology used to solder components onto circuit boards. When carrying out reflow soldering process, attention should be paid to preparation work, application of solder paste, preheating, welding, inspection and repair, as well as cooling and packaging steps. By mastering these key points, the quality and efficiency of reflow soldering process can be ensured, thereby improving the reliability and performance of electronic products.