The accuracy of industrial CT scanning

Release time:2023-12-25Publisher:Jeenoce

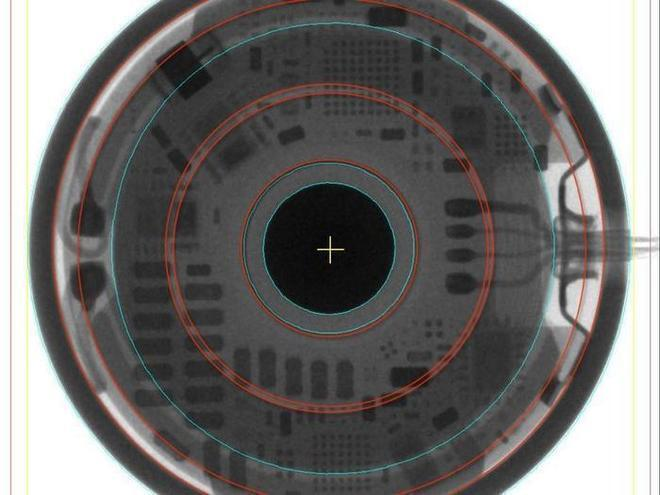

Industrial CT (computed tomography) is a non-destructive testing method used to examine and analyze industrial products. It uses X-rays or ray beams to pass through objects and scan them at different angles, and then reconstructs a three-dimensional image of the object through a computer.

Its accuracy depends on multiple factors:

Resolution: The resolution of industrial CT determines the size of the smallest details and features it can detect. Higher resolution usually means higher accuracy.

The quality of X-ray sources and detectors: The performance and accuracy of X-ray sources and detectors directly affect the quality of scanning and the accuracy of reconstructed images.

Scanning parameters: The parameters used during scanning, such as scanning angle, sampling interval, etc., can affect the quality and accuracy of the reconstructed image.

Calibration and calibration: Correct equipment calibration and calibration are key to ensuring accuracy. Calibration may involve precise positioning of the scanning system or correcting system errors.

The density and absorption of materials: Different materials have varying degrees of absorption of X-rays, which may affect the contrast and clarity of the image.

At present, the accuracy of industrial CT can reach the sub micron (hundreds of nanometers) level or even higher, but the actual accuracy depends on various factors, including equipment model, technical level, scanning parameters, calibration methods, and the characteristics of the tested object.

Generally speaking, the accuracy of industrial CT ranges from a few micrometers to tens of micrometers, and there are also sub micron devices available, but there are also significant limitations, such as being able to scan very small samples. High end industrial CT systems and advanced scanning technology can achieve higher accuracy. For specific applications, if higher accuracy is required, more specialized and high-performance equipment may be required, and more complex scanning and image processing techniques may be required.

In practical applications, industrial CT is commonly used for quality control, defect detection, size measurement, and material analysis of precision components. For example, fields such as aerospace, automotive manufacturing, and electronic equipment manufacturing require high-precision industrial CT to detect small defects in components or accurately measure dimensions.

It should be noted that although industrial CT can provide high accuracy, actual manufacturing processes and measurement errors still need to be considered in practical applications. In addition, the material, shape, density and other characteristics of the sample may also affect the accuracy of industrial CT.

Overall, industrial CT can provide high-precision 3D images, but its accuracy is influenced by various factors. For specific applications, it is necessary to select appropriate equipment and parameters based on the required accuracy and characteristics of the detection object.