The Application of X-RAY Detection in SMT Patch Field

Release time:2023-12-21Publisher:Jeenoce

X-ray inspection is a very important quality inspection method in SMT production lines. By conducting X-ray inspection on welding points, problems such as poor welding and missing components can be effectively detected, thereby ensuring product quality. JEENOCE will introduce the basic principles, application scenarios, advantages, and future development trends of X-ray detection SMT.

1、 The basic principle of X-ray testing SMT

X-rays are a type of electromagnetic wave with strong penetrating ability. In SMT, X-rays are generated by accelerating voltage and irradiated onto the welding point. When X-rays are irradiated on a welding point, different materials exhibit different levels of X-ray absorption, resulting in different images on the image sensor. By analyzing these images, it is possible to determine whether there are defects in the welding points.

2、 Application scenarios of X-ray detection SMT

1. Detection of welding defects

In SMT, poor welding is a common quality issue. Through X-ray inspection, the internal structure of the welding point can be clearly presented, thereby determining whether there are problems such as poor welding. For some small welding points, even defects that cannot be observed by the naked eye, X-ray testing can accurately detect them.

2. Missing detection components

In the SMT production process, sometimes there may be missing components. Through X-ray inspection, it is possible to detect any missing components or other issues at the welding points. Meanwhile, X-ray testing can also detect issues such as incorrect placement of components.

3. Detection of metal foreign objects

Metal foreign objects are a common quality issue in SMT. Through X-ray inspection, metal foreign objects around the welding points can be detected, ensuring the safety of the product.

3、 The advantages of X-ray testing SMT

1. High precision

X-ray testing has very high accuracy and can detect some small defects and problems. Meanwhile, due to its non-contact detection method, it will not cause any damage to the welding points, thus ensuring the quality of the product.

2. Fast and efficient

X-ray testing has the advantages of being fast and efficient. In the production line, X-ray inspection equipment can quickly detect welding points and output inspection results, thereby ensuring the stability and efficiency of the production line.

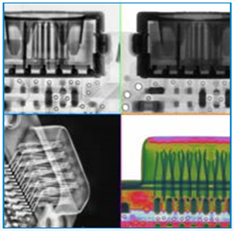

3. Visual display

X-ray inspection can present the internal structure of welding points in the form of images, thus making it more intuitive to determine whether there are quality problems. Meanwhile, X-ray testing can also simultaneously detect multiple welding points, improving detection efficiency.

4、 Future development trends

1. High resolution imaging technology

With the continuous development of technology, the resolution of X-ray testing equipment will become higher and higher in the future. High resolution imaging technology can present the internal structure of welding points more clearly, thereby more accurately identifying quality issues.

2. Automated detection technology

Automation technology is one of the future development trends. In the field of X-ray testing, automation technology can improve detection efficiency, reduce costs, and reduce the impact of human factors on detection results. In the future, with the continuous development of machine vision and other technologies, automated detection technology will become increasingly mature.

3. Multi functional integration

In the future, X-ray testing equipment will develop towards multifunctional integration. For example, X-ray testing equipment can be integrated with other equipment on the production line to achieve automated production and management. At the same time, multiple detection methods can be integrated to achieve comprehensive application of multiple quality inspections.

In summary, X-ray testing SMT is a very important quality inspection method. By conducting X-ray inspection on welding points, problems such as poor welding and missing components can be effectively detected to ensure product quality. In the future, with the continuous development of technology, more and more new technologies will be applied in this field and will become more mature and efficient, providing important guarantees and support for the sustainable development of the electronic manufacturing industry. This article will introduce the basic principles, application scenarios, advantages, and future development trends of X-ray detection SMT, hoping to provide some reference and help for everyone.