What issues should be noted during reflow soldering?

Release time:2023-12-20Publisher:Jeenoce

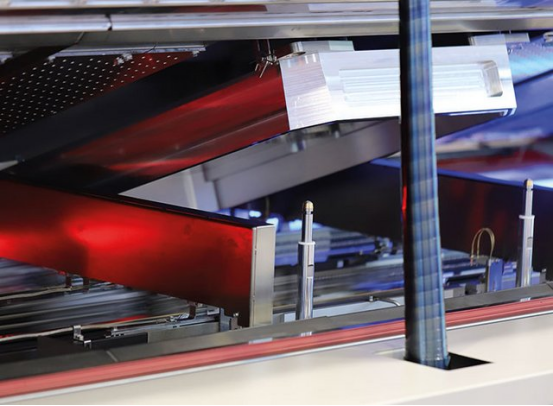

During the reflow soldering process, attention should be paid to the following issues:

1. Cleaning: Before reflow soldering, the welding area, solder paste, oxides, etc. must be cleaned thoroughly. At the same time, it is also necessary to ensure the cleanliness of the inside and outside of the equipment.

2. Temperature control: The temperature of the reflow soldering furnace must be controlled within the set range to ensure welding quality. The temperature curve setting should be adjusted according to the product characteristics.

3. Welding time: The welding time should be adjusted according to the characteristics of the welding material and equipment to avoid excessive or insufficient welding.

4. Welding pressure: The magnitude and direction of welding pressure should be uniform to avoid the occurrence of welding defects.

5. Welding environment: Reflow soldering should be carried out in a clean and dust-free environment to avoid the impact of dust, foreign objects, etc. on the welding quality.

6. Equipment maintenance: Reflow soldering equipment should be regularly maintained to ensure its normal operation and extend its lifespan.

7. Safety measures: When performing reflow soldering operations, attention should be paid to safe operations to avoid non-standard operations and accidents.

In short, the reflow soldering process requires strict control of various parameters to ensure welding quality, thereby ensuring product quality and stability.