Can the X-RAY inspection machine detect defects in transparent glass materials?

Release time:2023-12-19Publisher:Jeenoce

Glass is a common material in nature, which neither absorbs nor reflects light. This results in glass being a transparent substance in our visual system, and some substances such as water, ice, and transparent glue do not absorb or reflect light. These types of materials often encounter situations in practical use that require testing for OK, such as fixing two components with glue, People often worry about the glue not sticking properly or the presence of bubbles in the glue causing poor adhesion. Today, JEENOCE will talk about the issue of X-ray inspection function not being able to detect internal defects in materials such as glue and glass. Let's take glass as an example.

Firstly, we need to clarify that this is definitely a combination of glass, adhesive, and other non transparent components. If it is pure transparency, there is no need for an X-ray inspection machine. After all, transparent objects can be seen clearly with a magnifying glass and the naked eye. X-ray inspection machines are X-ray based devices that can detect internal problems in various materials, such as metals, ceramics, plastics, etc. However, for transparent materials like glass, The X-ray inspection machine cannot directly detect the problems present.

Firstly, glass is a transparent material, and its internal structure cannot be directly detected by X-rays. The atomic structure of glass makes its absorption of X-rays very low, so X-rays cannot penetrate the glass and return useful information.

Secondly, X-ray inspection machines typically need to focus X-rays on the material to be tested in order to obtain sufficient information. However, due to the transparency of glass, X-rays cannot be focused on it.

In addition, there are some technical issues with using X-ray inspection machines to inspect glass. For example, the detector of an X-ray inspection machine needs to be able to accurately measure X-rays, but glass may absorb X-rays and cause interference. Meanwhile, small defects in glass may also cause X-ray scattering, thereby affecting the accuracy of detection results.

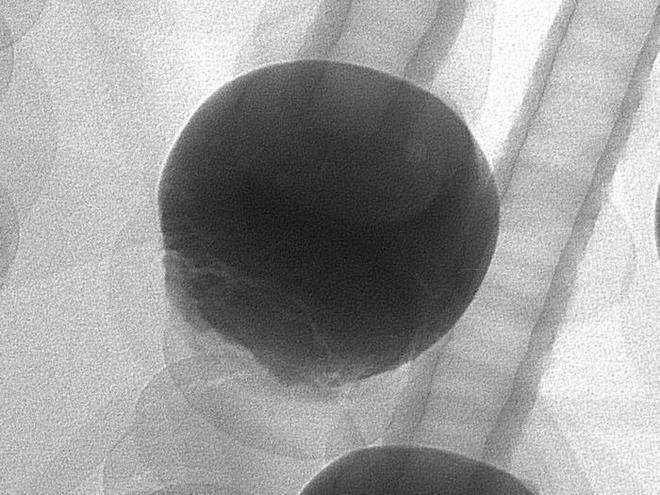

Therefore, for materials like glass, X-ray inspection machines are usually not used for testing. If it is necessary to detect problems in the glass, other more suitable detection techniques such as optical microscopy, scanning electron microscopy, etc. can be used.