Application scope of reflow soldering

Release time:2023-12-01Publisher:Jeenoce

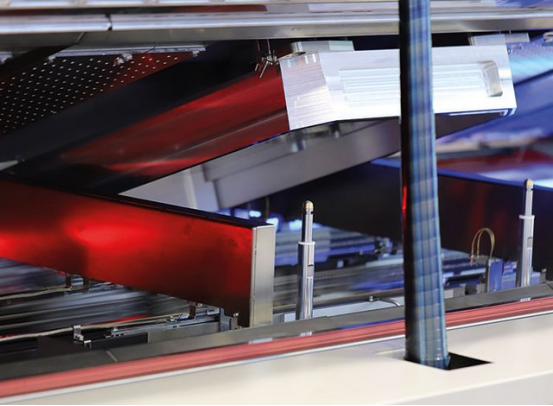

Reflow soldering is mainly used to weld circuit boards that have already been installed with components. By heating, the solder paste is melted to fuse and weld the SMT components with the circuit board solder pads. Then, through the cooling of reflow soldering, the solder paste is cooled to solidify the components and solder pads together.

From a production process perspective, reflow soldering is mainly used in SMT production processes, to weld circuit boards that have already been installed with components. Through the reflow soldering furnace welding process, the components and circuit boards are fused and welded together.

If we look at the overall application range, then its application range is very wide. Nowadays, many electronic products are developing towards integration, and most circuit boards use SMT technology. When using SMT technology, reflow soldering must be used. So nowadays, electronic and electrical products, aerospace technology, military products, and other electrical products that require electricity in all aspects of people's lives must be produced using reflow soldering.

Reflow soldering technology is actually a sophisticated process soldering technique, and the biggest advantage of this technology is that it can solder electronic components onto some small circuit boards, thereby meeting the needs of enterprises for circuit boards. From the perspective of production technology, reflow soldering is a welding process applied in SMT technology. In practical applications, it can be said that reflow soldering is applied in all aspects of our production and life.