The importance of X-RAY detection equipment in the SMT industry

Release time:2023-12-01Publisher:Jeenoce

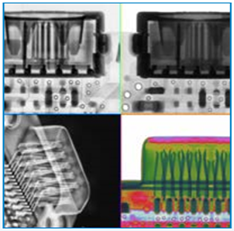

X-RAY detection equipment plays a crucial role in the SMT (Surface Mount Technology) industry. SMT is the mainstream technology in the modern electronic assembly industry, which involves directly soldering small components (such as resistors, capacitors, and integrated circuits) onto printed circuit boards. The following is the importance of X-RAY detection equipment in the SMT industry:

1. Non destructive testing: X-RAY testing can provide a non-destructive internal view of SMT production lines, allowing engineers to see the internal structure of printed circuit boards, including parts that are not visible to the naked eye, such as BGA, CSP, and other bottom solder joints.

2. Improve production quality: Through X-RAY testing, the production line can timely detect welding defects, such as virtual welding, solder ball offset, bridging, etc., greatly improving product reliability and production quality.

3. Cost saving: Timely detection and correction of production defects can avoid mass production of defective products, reduce rework and waste, and thus save costs.

4. Adapt to the trend of miniaturization and high-density assembly: With the continuous reduction of component size and the high-density assembly of circuit boards, traditional optical detection methods can no longer meet the requirements in some cases. X-RAY detection can provide higher resolution and deeper views.

5. Enhancing competitiveness: Manufacturers with high-quality X-RAY testing capabilities often gain higher customer trust and enhance their competitiveness in the market.

6. Meet strict standard requirements: For certain products with high reliability requirements, such as aviation, medical, and military products, X-RAY testing is an essential step to ensure product quality and safety.

In summary, X-RAY testing equipment provides a powerful tool for the SMT industry, which can effectively detect and correct various defects in production, ensuring high quality and reliability of products. With the continuous progress of electronic assembly technology, the importance of X-RAY detection in the SMT industry will further increase.