Discussion on the Advantages and Characteristics of Curve Splitter

Release time:2023-11-10Publisher:Jeenoce

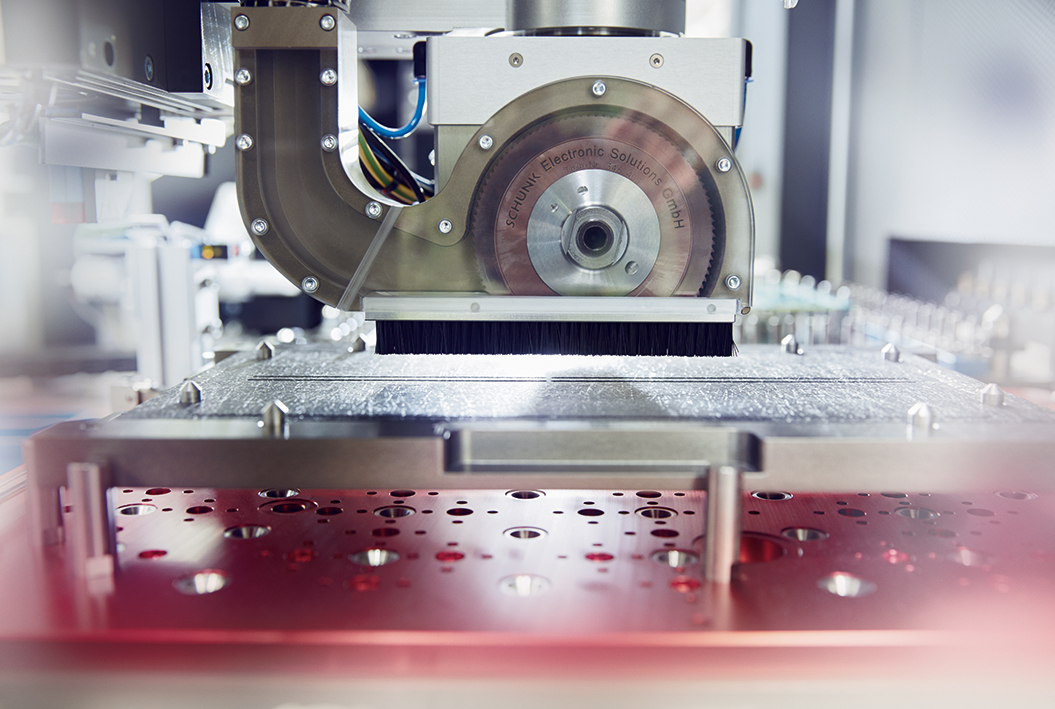

Curved dividing machine, also known as milling cutter dividing machine, is different from other types of dividing machines. It mainly uses a high-speed rotating spindle to drive a milling cutter to high-precision segment multiple connected PCB boards according to the programmed path.

Curve splitting machines (milling cutter splitting machines) have replaced manual breaking, V-CUT or PUSH cutting defects, greatly improving product quality and reducing scrap rates.

Features of the new floor mounted curve divider:

Equipped with a high pixel CCD magnifying lens, auxiliary program demonstration and editing simulation function, higher accuracy, clearer images, and more convenient operation.

The design of a single duplex platform facilitates product segmentation, conversion, retrieval, and placement, improving workability and efficiency.

The service life management monitoring of milling cutters. After cutting to a certain distance, the milling cutter will automatically rise/fall to the position of another uncut blade according to the setting. The up and down distance and number of times can be freely set according to the length of the blade to extend the service life of the milling cutter.

Circuit breaker protection, when the machine comes to an emergency stop, the spindle will first lift before stopping operation; After the spindle is turned on for n seconds, the machine can only proceed with board splitting work.

Program editing can be taught manually, with functions such as import and export, multi angle board copying, path copying, editing, and modification, accurately simplifying program production time.