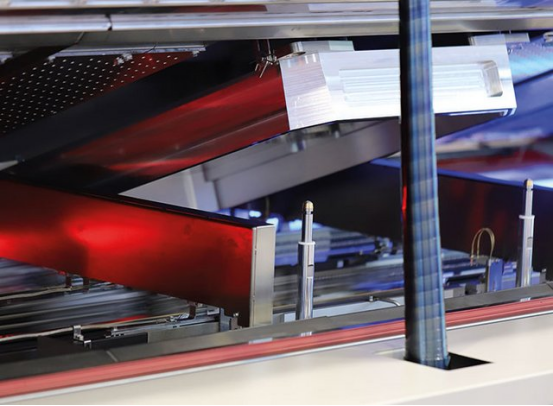

Principle of reflow soldering hot air heating

Release time:2023-10-16Publisher:Jeenoce

Reflow soldering is a commonly used electronic manufacturing welding technology, in which hot air heating is a key link. The sharing principle of JEENOCE is as follows:

1. Hot air heating device: Reflow soldering equipment is usually equipped with a hot air heating device, consisting of fans, heaters, and air ducts. The fan sucks in air from the outside, heats it up with a heater, and then sends it to the welding area through an air duct.

2. Welding heat transfer: The heated air forms a hot air flow in the welding area, heating the welded workpiece. The heat diffuses to the surrounding area through the heat transfer method of the welding material, ultimately reaching the temperature of the melting point of the welding material.

3. Welding temperature control: In order to ensure welding quality, it is necessary to accurately control the welding temperature. Reflow soldering equipment is usually equipped with a temperature control system to monitor and control the heating temperature of the welding area.

4. Welding time control: Welding time is also a key factor affecting welding quality. Reflow soldering equipment is usually equipped with a time control system to control the time and duration of the welding process.

In summary, the principle of hot air heating in reflow soldering is to form a hot air flow in the welding area through heated air, heating the welding workpiece, and controlling the welding temperature and time through temperature and time control systems to achieve the best welding effect.