Advantages:

Nordson Dage open, transmissive X-ray tube

Feature resolution <0.95 μ m

At the maximum 160KV tube voltage and 3W target power, the sub micron characteristic resolution can still be achieved.

With Nordson Dage's 1.33 megapixel, 10 frame / s CMOS flat panel detector, real-time mode image enhancement can be achieved with long service life.

2000 times geometric magnification, 7500 times system magnification

Maximum sample size: 29 "x 22.8" (736 x 580 mm)

The maximum inclination angle can reach 65 degrees with the same magnification

24 "TFT LCD display

Automatic detection does not require any programming skills

High definition real-time image

Micro CT options

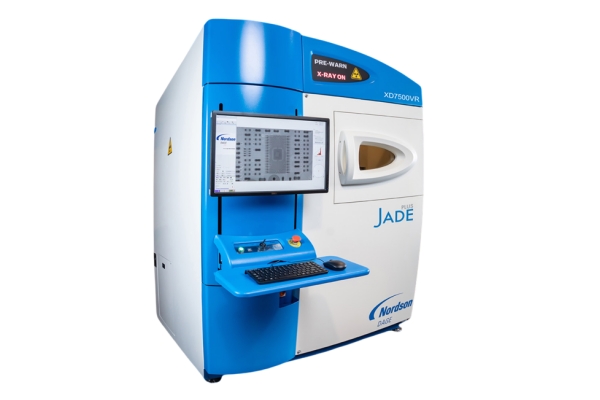

Nordson Dage, the only company specialized in X-ray electronic testing, provides Nordson Dage xd7500vr jade FP X-ray testing system, which uses the latest flat panel detector technology to provide market-oriented, efficient and clear real-time image product testing. High specification system configuration is superior to similar competitors. Nordson Dage open and transmissive X-ray tube is equipped with filament technology with long service life and 1.33 million CMOS flat-panel detector, which makes the system have the highest cost performance in real-time high magnification and high-resolution X-ray imaging technology. The X-ray tube is designed at the bottom. The movement of the operating platform and the inclination of the image detector are designed through the isocenter. All controls can be completed through simple click operation of the software without rocker operation. In this way, the safe and collision free detection of the product can be realized. All functions can be automatically detected simply and quickly without complex programming techniques.

Parameters:

• Nordson Dage vr950 new technology, open, transmission X-ray tube:

– all voltages achieve a characteristic resolution of <0.95 microns

– maximum voltage 160KV, target power: 3W

– long service life of filament assembly

– automatic pressure stabilizing light tube

• 2000x optical magnification (7500x system magnification)

• simple, collision free, high magnification, high resolution detection system:

– the above features are also available for detection at the tilt angle

– without rocker, mouse click operation

• maximum sample test size: 29 "x 22.8" (736 x 580 mm), magnification

• maximum inspection size: 20 "x 17.5" (508 x 444 mm)

• tilt angle detection up to 65 degrees

– test point 360 ° rotation detection

– the isocenter operation platform structure ensures the image resolution within the visual range.

• 1.33 megapixel (1536*864 pixel ratio) CMOS digital detector with long service life:

– 10 frames / second holographic "real time" imaging system

– real time image enhancement

• 16 bit digital image processing system

• anti vibration control treatment

• 24 "TFT LCD operation display

• Nordson Dage X-ray image operation software includes the following functions:

– automatic or manual component failure analysis, including BGA and QFN

– simple, fast and stable automatic detection program

– calculation of penetration hole filling percentage

– precise measurement function

– automatically or manually measure the proportion of bubbles in the chip

– patented X-image navigation map to facilitate defect location

– easy to use without complicated rocker operation

• totally enclosed lead shielding safety system

– X-ray radiation leakage <1 μ Sv/hr

– comply with all international standards

– radiation exemption

Windows10 64 bit operating system

System:

• size: 57x67x77.5 "(W x L x H)

• size: 1450x1700x1970mm (W x L x H)

• system mass: 1950 kg (4300 lb)

• maximum sample weight: 5 kg

• power supply: single phase 200 – 230 volts, 16 Amps

• maximum power: 1000 watts

Pre:没有了!