Exploring the Eye of Intelligent Manufacturing: Unveiling the Mysterious Veil of Online AOI for Printed Circuit Boards (PCBs)

Release time:2024-08-16Publisher:Jeenoce

In the vast universe of precision electronic manufacturing, every PCB is the crystallization of precision craftsmanship and cutting-edge technology. They are like stars in the universe, small but containing infinite possibilities.

In these miniature worlds, the precise layout of every wire and component is the ultimate pursuit of intelligence and innovation.

On this micro battlefield, AOI (Automated Optical Inspection) has become an indispensable guardian with its extraordinary insight.

AOI, as the "smart eye" in the field of intelligent manufacturing, utilizes advanced optical imaging technology and complex image processing algorithms to perform high-speed and high-precision comprehensive scanning and inspection of PCB boards.

It can accurately identify any tiny flaws or defects from intricate circuits and components in a very short period of time, ensuring that every PCB board meets almost perfect quality standards.

When someone curiously asks, "What is online AOI for circuit board PCB

This is not just a technical inquiry, but also an exploration of the pursuit of precision and efficiency behind intelligent manufacturing.

Janos Electronics, as a pioneer in this field, will lead you to experience together

1、 Initial acquaintance with AOI: Guardian of Intelligent Detection

Definition of AOI Technology

AOI is a detection technology based on optical principles, which uses high-resolution cameras and advanced image processing algorithms to automatically detect surface defects of PCBA (printed circuit board assembly).

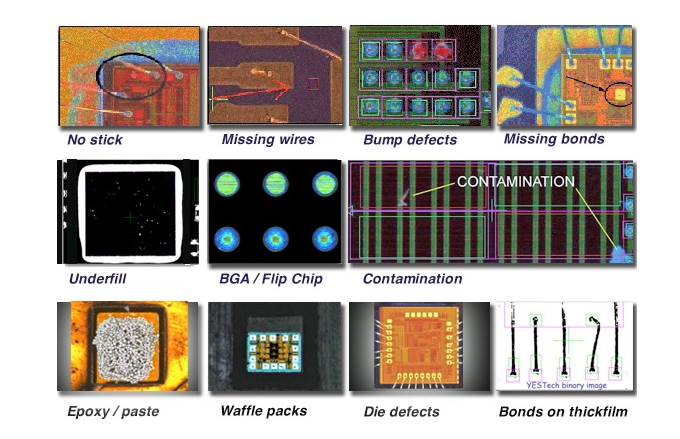

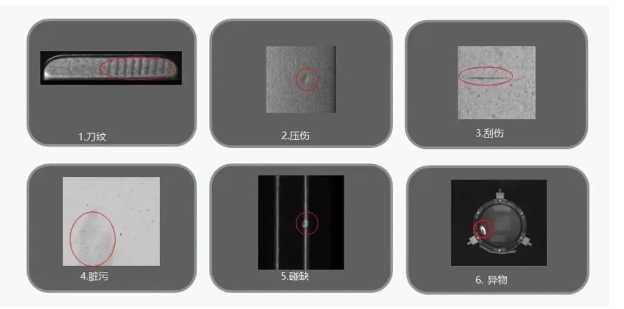

By capturing images of PCBs and their components and comparing them with preset quality standards, AOI can quickly and accurately identify various defects, such as component offset, monument, reverse white, multiple pieces, missing parts, solder joint issues, etc

1、 In depth interpretation of AOI technology

Jinnuo Company is well aware that the core of AOI technology lies in its high-precision and high-efficiency detection capabilities.

By integrating industry-leading high-resolution cameras and intelligent image processing algorithms, AOI can not only capture every subtle component change on the PCB board, but also complete complex image comparison and defect recognition in milliseconds.

This unprecedented detection accuracy and speed have laid a solid foundation for the high-quality manufacturing of electronic products.

2、 Additional advantages of using AOI

Enhance market response speed:

In the view of Innolux, the application of AOI technology also means faster market response speed.

Through real-time detection and feedback, we can quickly adjust our production strategy to ensure that our products quickly adapt to changes in market demand and seize market opportunities.

Promote process optimization and innovation:

The data provided by AOI equipment is not limited to defect recognition, but also a valuable resource for process optimization.

Through in-depth analysis of detection data, we can identify potential problems in the production process, promote process innovation, and continuously improve the comprehensive performance and competitiveness of products.

Strengthening brand image and trust:

In the fiercely competitive electronic market, product quality is the foundation for enterprises to establish themselves.

Jinnuo Company insists on adopting AOI technology, which fundamentally guarantees the excellent quality of its products, enhances customers' trust and loyalty to the brand, and lays a solid reputation foundation for the long-term development of the enterprise.

3、 Potential challenges of not using AOI

Missed market opportunities:

Faced with rapidly changing market demands, if enterprises still rely on traditional manual testing methods, they will undoubtedly miss the valuable opportunity to respond quickly to the market, leading to a decline in competitiveness.

Technological barriers and risks of backwardness:

With the continuous advancement of electronic technology, high-precision and high-efficiency detection technology has become a standard in the industry.

If enterprises fail to introduce advanced technologies such as AOI in a timely manner, they will face technological barriers and risks of falling behind, making it difficult for them to establish themselves in the fierce market competition.

2、 Janos Electronics: a leader in the AOI field

1. Leader of technological innovation

In the rapid development of intelligent manufacturing, Suzhou Jinnuo Electronics Co., Ltd. has always played a leading role in technological innovation.

We are well aware that continuous technological advancement is the key to driving industry development.

Therefore, we continuously invest in research and development, exploring the forefront of AOI technology to ensure that our solutions always stay at the forefront of the industry.

2. Deep cooperation, jointly building the cornerstone of quality

In order to bring the highest quality AOI detection technology to customers, Innolux Electronics has established a deep partnership with industry giant Nordson.

We have jointly introduced Nordson's flagship product - YESTECH M2 series AOI detection system. This collaboration not only provides us with top-notch technical support, but also ensures that our solutions can fully meet the needs of the local market.

3. YESTECH M2 series AOI: a model of excellent performance

The YESTECH M2 series AOI detection system is renowned for its high speed, high precision, and high stability.

The high-speed image acquisition and processing capability significantly improves detection efficiency;

High precision detection algorithms ensure that every tiny defect can be accurately captured;

The high stability performance provides customers with long-term reliable quality assurance.

These outstanding performances have made the YESTECH M2 series AOI a trusted choice for many electronic manufacturing companies.

4. Customized services to meet diverse needs

We are well aware that the production process and requirements of each enterprise are unique.

Therefore, while providing the M2 series AOI detection system, Innolux Electronics also offers customized service solutions for customers.

We optimize and adjust the detection system according to the actual needs of our customers, ensuring that it can be perfectly integrated into their production processes, thereby improving overall production efficiency and product quality.

3、 Why choose Innolux's AOI solution?

1. Top technology, precise protection

Janos Electronics, in collaboration with industry giant Nordson, proudly launches the YESTECH M2 series AOI detection system.

This system is equipped with cutting-edge optical imaging and image processing technology, capturing the slightest flaws on PCB boards with unimaginable precision - whether it is small component offsets or subtle soldering defects, they are all exposed.

We promise that every inspection is a rigorous commitment to product quality, allowing your product to win more trust in the market.

2. Deep cultivation in the industry, worry free customization

Whether your business field is at the forefront of consumer electronics trends, precision craftsmanship in automotive manufacturing, strict standards in medical equipment, or innovative exploration in the new energy industry, Jinnos Electronics can provide customized AOI solutions.

We have rich and cooperative experience, so we can deeply understand the unique needs of each industry, with a professional perspective and flexible strategies, to ensure that your production line is efficient and smooth, and easily respond to the diverse challenges of the market.

3. Intelligent integration, efficient upgrading

As a pioneer in the field of intelligent manufacturing, Jinnos Electronics excels in seamlessly integrating advanced AOI technology into your SMT assembly line and automated assembly process.

We have a professional team of integration experts who can tailor our products to your production environment. Through precise debugging and optimization, we can achieve a leap towards intelligent production lines, greatly improving production efficiency and flexibility.

4. Professional escort, accompanying throughout the process

At Innolux Electronics, we firmly believe that high-quality service is the key to success.

Therefore, we have established a service team composed of industry elites who are not only skilled in technology, but also have profound industry experience.

From the initial scheme design of the project, to the installation and debugging of the system, to the later maintenance, we will accompany you throughout the process to ensure that your AOI system always maintains the best state, making your production worry free.

4、 Interactive Moment: We will answer your AOI questions

Have you gained a deeper understanding of "Online AOI of PCB"?

AOI, also known as Automatic Optical Inspection, is an important part of SMT (Surface Mount Technology) production lines. It is like an intelligent eye, accurately capturing every detail to ensure product quality.

But the charm of AOI goes far beyond that. How can it integrate with other intelligent manufacturing technologies?

How can we help enterprises improve production efficiency and competitiveness?

Let's discuss together in the comment section to deepen our understanding of AOI technology.

Do you still have questions or face challenges regarding AOI technology on the path of exploring intelligent manufacturing?

For example, how to choose the most suitable AOI system for your production line?

How to optimize AOI detection parameters to improve detection accuracy and efficiency?

Or how to effectively integrate AOI data to achieve continuous improvement in production processes?

Leave your question in the comment section, and the professional team of Jinnos Electronics will be dedicated to answering your questions and working together to solve the problems in intelligent manufacturing.

We also look forward to hearing your unique insights or successful case sharing on AOI technology.

Your experience may inspire other companies to jointly promote the development of the intelligent manufacturing industry.

Whether it's technological innovation, application practice, or market trends, we welcome everyone to freely express themselves in the comments section and explore the infinite possibilities of intelligent manufacturing together with Ginos Electronics and many industry colleagues.

Finally, on the vast stage of intelligent manufacturing, JNOS Electronics collaborates with Nordson YESTECH M2 AOI inspection system to empower every PCB with the power of technology, illuminating the future with the light of quality.

Let's witness the glorious chapter of intelligent manufacturing together!