Suzhou Jeenoce Electronics Join Hands with Klingelnberg Gear Inspection Machine: High-precision Technology Empowers a New Era of Intelligent Manufacturing

Release time:2024-08-07Publisher:Jeenoce

Core Keywords: Klingelnberg Gear Testing Machine, Precision, Jinos Electronics, Manufacturing Industry

Date & Source

Publication Date: 2024-08-07

Source Note: Authoritative Technology News | Officially Released by Jinos Electronics

I. Introduction

In today's era where smart manufacturing and precision manufacturing are increasingly intertwined, Suzhou Jinos Electronics Co., Ltd., leveraging its profound industry experience and technological innovation capabilities, has partnered with the globally renowned Klingelnberg Gear Testing Machine to jointly set a new benchmark for precision upgrades and quality control in the manufacturing industry. This article delves into how this formidable collaboration is leading industry transformation and elevating smart manufacturing standards.

II. High-Precision Detection Technology: Adhering to the VDI/VDE 2612 Grade I Precision Standard

Keywords: VDI/VDE 2612 Grade I Precision, Gear Testing Machine, High-Precision Measurement

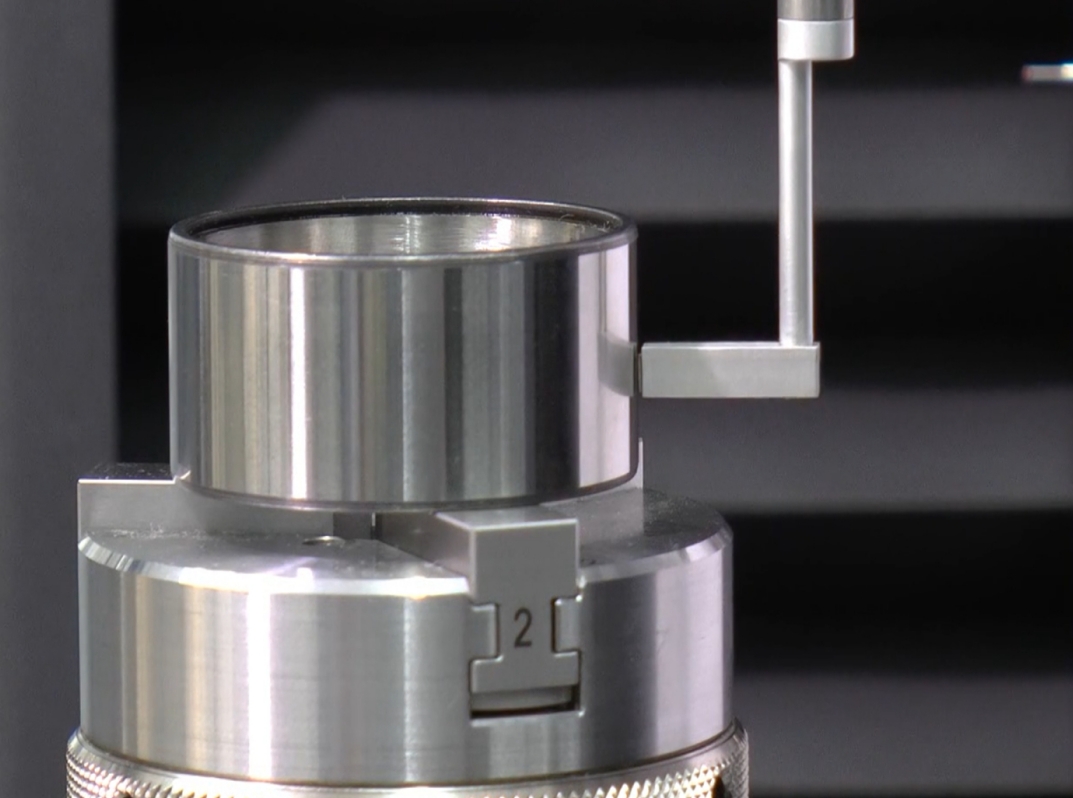

Content Elaboration: Renowned for its exceptional VDI/VDE 2612 Grade I precision standard, the Klingelnberg Gear Testing Machine accurately captures and quantifies critical geometric parameters such as tooth pitch deviations, tooth profile errors, and helix deviations of gears, ensuring the accuracy and reliability of measurement results. As a promoter of this technology, Jinos Electronics facilitates customers in achieving a new leap in quality control.

III. Multi-Axis Measurement Technology: A Powerful Tool for Comprehensive Analysis of Complex Gear Parameters

Keywords: Multi-Axis Measurement, Complex Gear Parameters, P26 Gear Measuring Center

Content Elaboration: High-end models like the Klingelnberg P26 Gear Measuring Center employ advanced 4-axis or multi-axis measurement technology, enabling multi-dimensional and comprehensive detection of gears. This technology not only covers basic parameters but also delves into complex parameters like helix angles and tooth alignment errors, ensuring that each device provided by Jinos Electronics' automation solutions precisely matches customer needs, enhancing gear manufacturing precision and efficiency.

IV. Collision Protection Mechanism: Safeguarding Smart Manufacturing

Keywords: Collision Protection, Production Safety, Equipment Durability

Content Elaboration: In high-speed, high-precision measurement environments, the Klingelnberg Gear Testing Machine is equipped with advanced sensors and algorithms that effectively prevent potential collision risks, safeguarding workpieces and equipment. Jinos Electronics emphasizes this safety mechanism in automation line integration, ensuring production process stability and reducing unexpected downtime and maintenance costs.

V. Digital Integration Solutions: Ushering in a New Era of Smart Manufacturing

Keywords: Digital Integration, Real-Time Data Collection, Smart Manufacturing

Content Elaboration: Beyond providing high-precision testing equipment, Jinos Electronics is dedicated to crafting comprehensive digital factory SMT lines and automation solutions. By seamlessly integrating high-precision devices like the Klingelnberg Gear Testing Machine, it enables real-time data collection, analysis, and feedback, boosting production efficiency and product quality. This offers customers a flexible, intelligent production management experience, enabling them to swiftly respond to market changes.

VI. Professional Consultation and After-Sales Service: A Solid Foundation for Customer Success

Keywords: Professional Consultation, After-Sales Service, Technical Support

Content Elaboration: Jinos Electronics offers customers comprehensive support ranging from selection consultation, installation and commissioning, to after-sales service. The company boasts a professional technical team that ensures customized solutions and technical support for rapid equipment deployment and maximum efficiency. Additionally, a robust after-sales service system guarantees timely and effective resolution of customer issues, providing unwavering support throughout the customer journey.

VII. Conclusion

The collaboration between Suzhou Jinos Electronics Co., Ltd., and the Klingelnberg Gear Testing Machine represents not just a fusion of high-precision detection technologies but also an innovative practice in the field of smart manufacturing. Looking ahead, Jinos Electronics will continue to uphold its commitment to technological innovation and quality excellence, offering the manufacturing industry more outstanding smart manufacturing solutions and driving sustained progress and development.