Industry leader JINOS Electronics analyzes: Why are the functions of SCHUNK depaneling machines more attractive than their prices?

Release time:2024-08-06Publisher:Jeenoce

Keywords: JINOS Electronics, SCHUNK Board Separator, Smart Manufacturing, High-Precision Cutting, Versatile Board Separation, Intelligent Control, Seamless Integration, Professional Service

I. Introduction

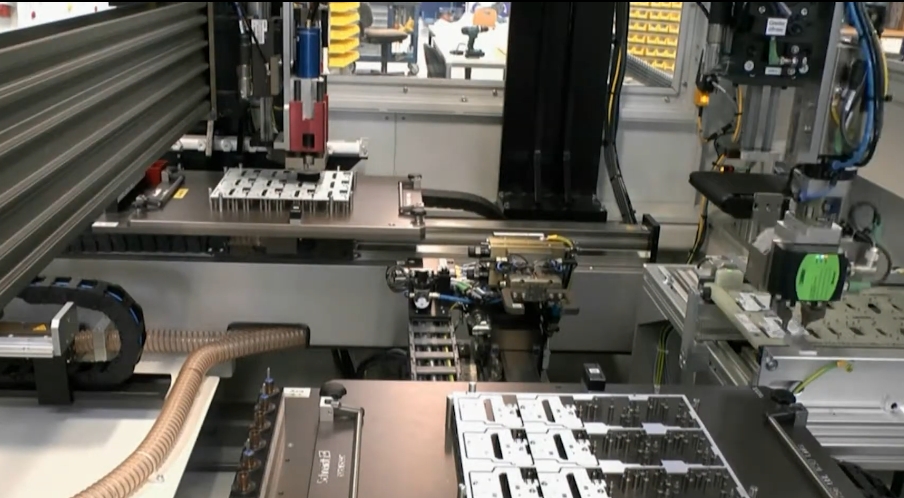

Amidst the wave of smart manufacturing, Suzhou JINOS Electronics Co., Ltd. has firmly established itself at the forefront of the industry with its profound technological foundation and precise insights into industry trends. As one of the company's core products, the German-imported SCHUNK Board Separator boasts powerful functions that far exceed its price tag, offering unprecedented production experiences and value enhancements to customers. This article delves into the various functions and advantages of the SCHUNK Board Separator.

II. High-Precision Cutting Technology, Forging Exceptional Quality

Functional Highlight: The SCHUNK Board Separator employs advanced cutting technology, achieving micron-level precision in cutting. Its remarkable capabilities extend to both straightness, parallelism, and intricate shapes and minute structures.

Advantage Analysis: Reduces waste rate and enhances raw material utilization; eliminates cracks, burrs, and other issues, ensuring flawless product appearance and internal structure; caters to the demands of high-end electronics for precision processing.

III. Versatile Board Separation Modes, Flexibly Meeting Diverse Needs

Functional Highlight: Supports multiple board separation modes, including straight, curved, and irregular shapes, allowing users to select based on actual requirements.

Advantage Analysis: Enhances production efficiency by reducing mold changing and setup time; minimizes equipment investment and maintenance costs; swiftly adapts to market changes, bolstering corporate competitiveness.

IV. Intelligent Control System, Pushing Production Efficiency to New Heights

Functional Highlight: Equipped with an intelligent control system that monitors production status in real-time, automatically adjusts cutting parameters, and supports remote monitoring and fault diagnosis.

Advantage Analysis: Optimizes cutting paths and speeds, minimizing waiting and downtime; lessens human intervention and skill requirements, lowering labor costs; improves production safety by promptly identifying and addressing potential hazards.

V. Seamless Integration Capability, Shaping a New Ecosystem for Smart Manufacturing

Functional Highlight: As a crucial component of JINOS Electronics' digital factory solutions, the SCHUNK Board Separator seamlessly integrates into customers' automated production lines, enabling device interconnectivity.

Advantage Analysis: Elevates overall production efficiency through tighter collaboration among various processes; curtails transformation costs arising from device incompatibility; accelerates enterprises' transition towards smart manufacturing.

VI. Professional Service System, Ensuring Hassle-Free Operation

Functional Highlight: JINOS Electronics offers comprehensive technical support and after-sales services, encompassing equipment installation, commissioning, routine maintenance, technical training, and troubleshooting.

Advantage Analysis: Boosts customer satisfaction and loyalty by resolving various issues during usage; mitigates customer risks related to production disruptions and losses due to equipment failures; fosters long-term partnerships and opens up business opportunities and growth avenues for enterprises.

VII. Conclusion

In conclusion, the SCHUNK Board Separator, with its high-precision cutting technology, versatile board separation modes, intelligent control system, seamless integration capabilities, and professional service system, exhibits formidable competitiveness and market value in the smart manufacturing sector. Suzhou JINOS Electronics Co., Ltd. will continue to uphold the principles of technological innovation and service excellence, providing customers with even more superior smart manufacturing solutions and support, jointly driving the sustainable development and progress of the smart manufacturing industry.