New Benchmark in SMT Reflow Soldering Quality Control: Joint Efforts of JINOS Electronics and German REHM Reflow Ovens

Release time:2024-08-05Publisher:Jeenoce

In the relentless pursuit of intelligent manufacturing excellence, the quality of SMT (Surface Mount Technology) reflow soldering has become a crucial measure of electronic product reliability. Voiding, a hidden threat during the soldering process, not only jeopardizes product performance but also tests the technical prowess and commitment of enterprises. Suzhou JINOS Electronics Co., Ltd., a pioneer in the intelligent manufacturing sector, has partnered with German REHM reflow ovens to establish an efficient and precise quality control system for soldering, aiming to eradicate voiding at its source and lead the industry into new horizons.

I. German Engineering, Ensuring Precise Soldering

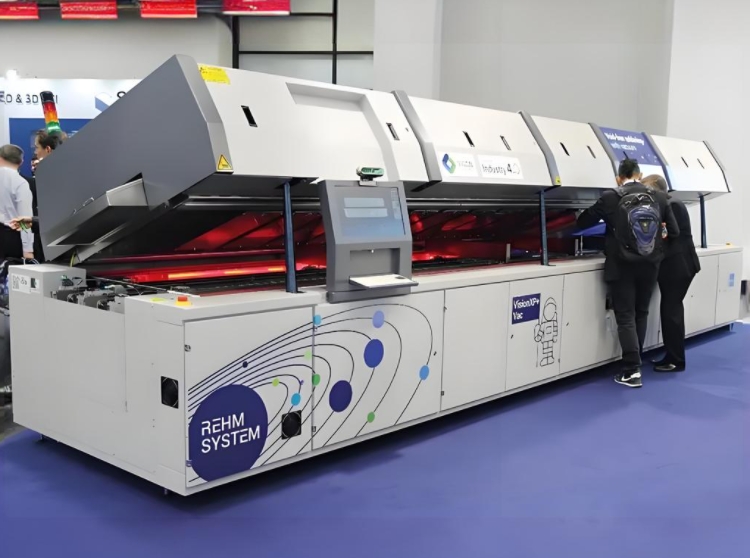

Renowned globally for their superior temperature control, stable operation, and meticulous craftsmanship, German REHM reflow ovens offer unparalleled precision in soldering. JINOS Electronics has chosen this high-end equipment to provide clients with unprecedented soldering accuracy and reliability. The REHM reflow ovens' precise temperature control system ensures perfect synchronization between soldering temperature and time, allowing the solder to fully melt and form a robust bond with the pads and component leads, effectively preventing voiding, bubbling, and other issues.

II. Stringent Selection of Materials and Components, Double Guarantee of Quality

In addition to top-notch equipment, JINOS Electronics rigorously selects high-quality electronic components and PCB boards to ensure optimal solderability and weldability. Furthermore, we use high-purity, low-impurity solder materials to provide a double layer of assurance for soldering quality.

III. Comprehensive Quality Control, Guarding Every Step

JINOS Electronics has established a comprehensive quality control system that scrutinizes every aspect from material entry to product delivery. We integrate cutting-edge inspection technologies such as SPI, AOI, and X-ray with the German REHM reflow ovens, offering a comprehensive, multi-layered monitoring of soldering quality. Moreover, we regularly maintain and inspect our soldering equipment and processes to ensure optimal performance.

IV. Process Optimization and Customized Services, Meeting Individual Needs

Tailoring to the specific needs and product characteristics of each client, JINOS Electronics offers personalized process parameter settings. By combining the advanced capabilities of German REHM reflow ovens with our own technological expertise, we customize optimal soldering solutions for our clients. From solder paste selection, printing parameter adjustments, to reflow temperature profile settings, we strive for precision matching to maximize soldering quality.

V. Talent Cultivation and Skill Enhancement, Forging a Professional Team

Recognizing the significance of talent in corporate growth, JINOS Electronics emphasizes operator skill development and enhancement. Through regular professional training and skill assessments, we continuously absorb international advanced technologies and concepts from our partnership with German REHM reflow ovens, enhancing our team's overall strength and competitiveness. We advocate standardized operation procedures and normative work habits, ensuring that every operator masters soldering processes and equipment operation techniques, providing clients with even more superior and reliable SMT reflow soldering solutions.

In conclusion, Suzhou JINOS Electronics Co., Ltd., in collaboration with German REHM reflow ovens, has set a new benchmark for SMT reflow soldering quality control. With our outstanding technical capabilities, rigorous quality control systems, and professional service teams, we are dedicated to providing clients with comprehensive, high-quality soldering solutions. Looking ahead, we will continue to uphold the enterprise spirit of innovation, excellence, and integrity, contributing to the advancement of intelligent manufacturing.