Suzhou Jienuosi Electronics: Klingelnberg Gear Measuring Instrument – Micron-Level Precision, Forging a New Foundation for Smart Manufacturing

Release time:2024-07-30Publisher:Jeenoce

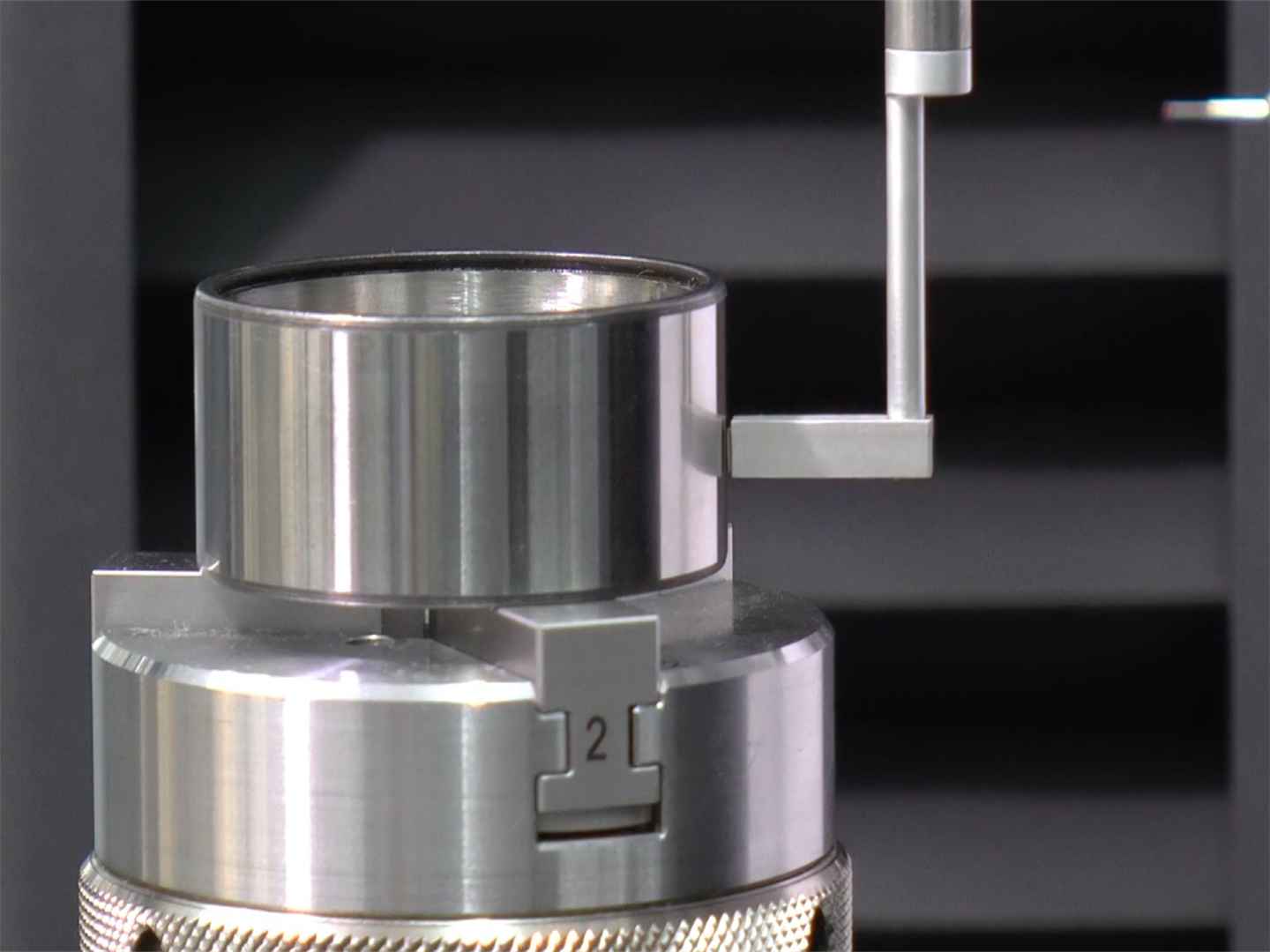

Amidst the intricate halls of smart manufacturing, Suzhou Jienuosi Electronics Co., Ltd. has laid the cornerstone of excellence and efficiency through technological innovation. Our close collaboration with Germany's Klingelnberg, particularly the introduction of their micron-level precision gear measuring instrument, showcases not only our technological prowess but also serves as a paradigm of profound integration between knowledge and practice.

Suzhou Jienuosi Electronics understands that amidst the tide of smart manufacturing, technological innovation is the vital force propelling the industry forward. The Klingelnberg gear measuring instrument we've introduced embodies this very principle. Equipped with advanced non-contact scanning technology and sophisticated algorithm analysis, it achieves micron-level accuracy in measuring various gear parameters such as tooth profile, pitch, and helix angle, ensuring optimal gear meshing quality. This technological integration not only enriches our product line but also elevates our knowledge base and technical prowess in the realm of smart manufacturing.

Automotive Industry Case Study: In the automotive sector, we partnered with a renowned automaker to elevate the quality inspection of their premium model's transmission gears to unprecedented heights. Leveraging the micron-level precision of the Klingelnberg gear measuring instrument, we successfully identified and adjusted minute errors in the gears, leading to a notable reduction in transmission noise and a significant enhancement in durability. This case study not only validates the effectiveness of our technology but also deepens our understanding of the pivotal role of high-precision measurement in enhancing automotive performance.

Consumer Electronics Case Study: During the production of consumer electronics, we assisted a client in integrating the Klingelnberg gear measuring instrument for precise measurement and adjustment of internal motor gears. This initiative resulted in a direct improvement in assembly yield, soaring from 95% to 99.5%, significantly reducing production costs and bolstering market competitiveness. This case further underscores the immense potential of micron-level precision in boosting production efficiency and product quality, enriching our knowledge about the significance of precision measurement in smart manufacturing.

[Professional Services & Continuous Innovation]

Suzhou Jienuosi Electronics goes beyond merely providing top-tier measurement equipment; we emphasize the seamless integration of technology and service. Our dedicated technical team and comprehensive after-sales support system offer a full spectrum of services, from needs analysis, solution design, equipment selection, to installation, commissioning, and training. Recognizing that continuous innovation and service upgrades are crucial for staying ahead in the smart manufacturing journey, we will continue to deepen our cooperation with international brands like Klingelnberg, explore new technologies and applications, and create greater value for our clients.

Conclusion:

Suzhou Jienuosi Electronics, in partnership with Klingelnberg, uses micron-level precision measuring instruments as the bridge, tightly linking technological innovation with practical knowledge. Through the validation of real-world cases and in-depth knowledge integration, we continually propel the development and progress of the smart manufacturing sector. Going forward, we will uphold the principles of "Technological Innovation, Exceptional Quality, and Superior Service," delivering even more professional, efficient, and comprehensive smart manufacturing solutions to our clients.