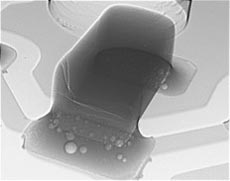

Example application of X-RAY glue detection

Release time:2024-07-19Publisher:Jeenoce

X-ray inspection can be used to detect the application of glue or other adhesives in the manufacturing process. This technology performs detection by sending X-rays to the material being tested and measuring the absorption level of the X-rays passing through. The presence of glue or adhesive can affect the penetration of X-rays, resulting in specific effects in X-ray images.

Through X-ray inspection of glue, the following objectives can be achieved:

Detecting the uniformity and suitability of glue: X-ray images can display the distribution of glue or adhesive to ensure that it is evenly coated or applied during the manufacturing process and meets design requirements.

Detecting the integrity of glue: X-ray testing can help detect defects in glue or adhesive, such as voids, cracks, or poor connections, to ensure the quality of manufactured products.

Detecting the adhesion between glue and other materials: X-ray images can display the adhesion between different materials, such as whether the glue completely covers the contact surface, and whether there are gaps or loose parts.

Overall, X-ray inspection provides a highly effective method for the application of glue or other adhesives in the manufacturing process, which can help manufacturers ensure the quality and performance of their products.