The main reasons for PCBA virtual soldering in SMT process

Release time:2024-07-17Publisher:Jeenoce

PCBA virtual soldering is a common quality issue in the electronic manufacturing process, which can lead to unstable circuit performance and even product failure. Understanding the causes of PCBA virtual soldering is crucial for improving product quality and reliability. This article will explore in detail the causes of PCBA virtual soldering, including production processes, material quality, environmental factors, and operational errors.

The impact of production process on PCBA virtual soldering cannot be ignored: during the soldering process, the control of parameters such as soldering temperature, soldering time, and soldering pressure is crucial. If the soldering temperature is too low or the soldering time is too short, the solder cannot fully melt and penetrate between the solder pad and the component pins, resulting in weak soldering and virtual soldering. On the contrary, if the welding temperature is too high or the welding time is too long, the solder may melt excessively and flow, resulting in irregular shapes of the solder joints, which can also easily cause virtual soldering. The control of welding pressure is also crucial, as too light or too heavy pressure may affect the welding quality.

2. Material quality is also an important factor affecting PCBA virtual soldering: the quality of materials such as solder, pads, and component pins directly affects the soldering effect. If the solder quality is poor, contains a lot of impurities, or there is an oxide layer on the surface of the solder pad and component pins, it will affect the wetting and adhesion of the solder, thereby increasing the risk of virtual soldering. Therefore, in the PCBA processing, reliable quality solder and components should be selected, and the surface of the solder pads and pins should be clean and free of oxidation.

3. Environmental factors can also have an impact on PCBA virtual soldering: for example, humidity and dust content in the air can affect soldering quality. Excessive humidity may cause water droplets to form on the solder surface, affecting the soldering effect; Dust may adhere to the surface of solder pads and component pins, reducing the wettability of solder. Therefore, in the PCBA processing process, the humidity and cleanliness of the workshop environment should be strictly controlled to ensure stable and reliable welding quality.

4. As mentioned above, some objective factors, such as operational errors, are also common causes of PCBA virtual soldering. Operators should strictly follow the operating procedures to ensure that each welding process is correctly executed. For example, before soldering, the solder pads and component pins should be cleaned to remove surface oxides and impurities; During the welding process, parameters such as welding temperature, time, and pressure should be well controlled; Quality inspection should be carried out after welding to promptly detect and address virtual welding issues. In addition to the above factors, there are other possible reasons that may lead to virtual soldering of PCBA. For example, aging or improper maintenance of welding equipment may lead to unstable welding quality; In addition, vibrations and impacts during the production process may also have adverse effects on welding quality. Therefore, during the PCBA processing, regular maintenance and upkeep of the welding equipment should be carried out to ensure stable and reliable equipment performance; At the same time, effective measures should be taken to reduce vibration and impact during the production process.

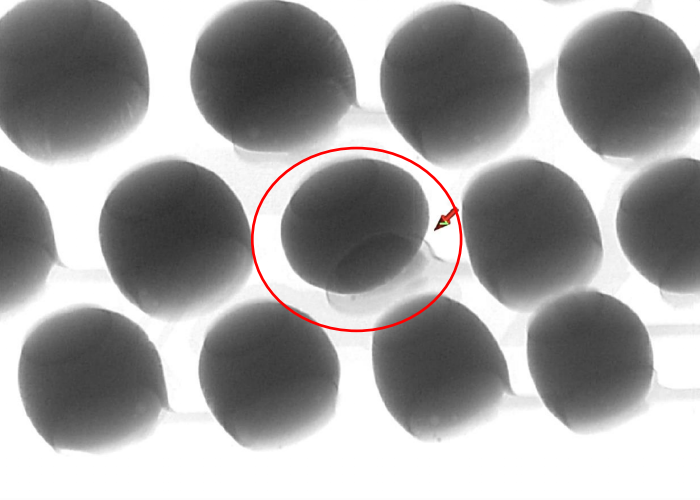

For the detection of virtual welding, X-RAY detection is currently the mainstream detection method in the market. Its visual detection method can be quickly and conveniently used, and can greatly improve detection efficiency.