Application industry of non-destructive testing for X-RAY equipment

Release time:2024-07-08Publisher:Jeenoce

In recent years, with the rapid improvement of China's economy and comprehensive national strength, the manufacturing industry has gradually become the mainstay of the national economy, and the testing industry in the manufacturing industry has become increasingly important. This undoubtedly provides broad development opportunities for the development of X-RAY non-destructive testing.

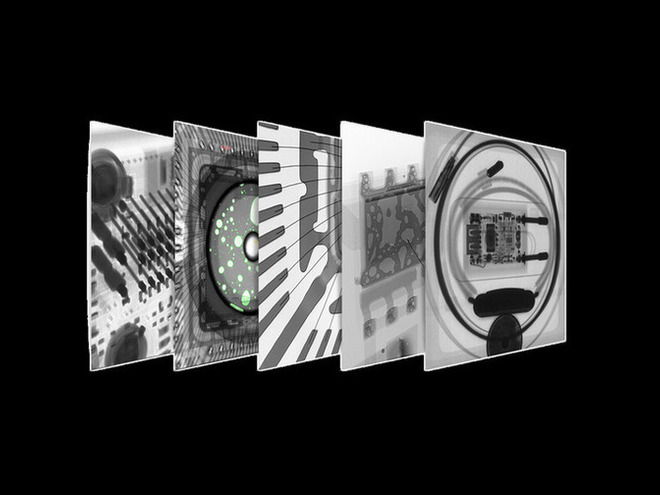

X-ray non-destructive testing refers to the use of the transmission characteristics of X-rays to reflect images with different grayscale values based on the different absorption properties of X-rays by different materials, in order to achieve defect detection of the tested object without damaging or affecting its performance. Today, let's take a look at which industries X-ray non-destructive testing can be applied to.

1. Lithium battery industry

According to the internal structure of lithium batteries, the cathode is encapsulated in the anode, and the intermediate isolation strip is used to prevent short circuits between the anode and cathode. If a finished battery is used, its internal structure cannot be detected. Using X-ray non-destructive testing technology to align the cathode and anode is a key step in ensuring the safety of monitoring data to ensure normal isolation status.

2. Electronic SMT industry

By using X-ray equipment to perform X-ray penetration testing on PCB boards or PCBA boards, it is possible to detect defects such as BGA and broken wires. By using X-ray non-destructive testing, the quality of the product can be greatly improved.

3. Aluminum casting industry

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computer, electronics, medical equipment, clock instruments, hardware products, aerospace, etc. In these industries, X-ray non-destructive testing can be used to detect defects in aluminum castings.

4. Steel cylinder and gas cylinder industry

The quality of steel cylinders and gas cylinders is closely related to people's life safety. For quality issues, the country has issued relevant national standards, and the use of X-ray non-destructive testing technology will greatly reduce the occurrence of steel cylinder and gas cylinder explosion accidents, ensuring the safety of consumers.

5. Radial pipe industry

Irregular tubes are generally used for winding sensors, and their quality directly affects the service life of the furnace body. The inductor is cooled by an AC converter and continuous cold water to avoid heating and failure of the furnace itself. The quality of small diameter and irregular pipe welds directly affects the normal operation of the entire machine. The use of X-ray non-destructive testing technology has become one of the key factors in quality control.