How to improve the welding quality and reliability of reflow soldering?

Release time:2024-06-28Publisher:Jeenoce

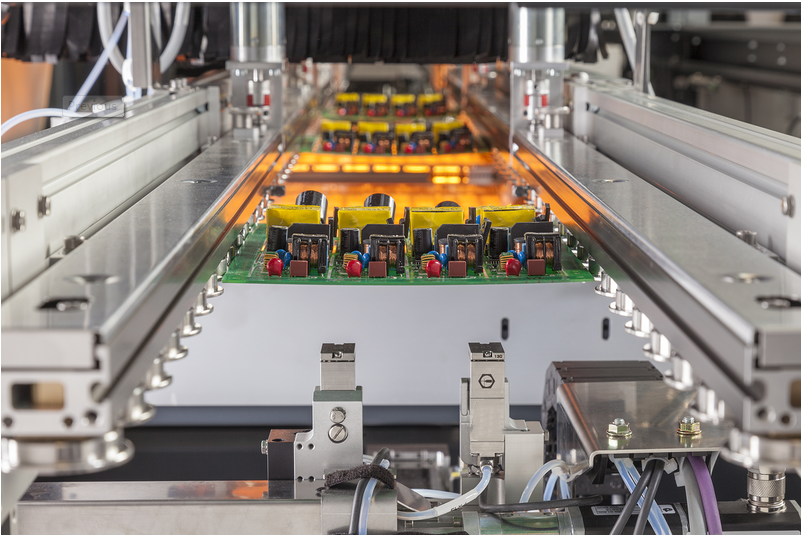

Improving the welding quality and reliability of reflow soldering can be approached from the following aspects:

1. Choosing the appropriate solder paste: Solder paste is the key material for reflow soldering. Choosing the appropriate grade and high-quality solder paste can help improve welding quality and reliability. Meanwhile, lead-free or lead-containing solder paste should be selected based on specific product and process requirements to meet environmental and performance requirements.

2. Optimize welding parameters: Based on the characteristics of different components, PCB boards, and solder paste, optimize the temperature curve and welding time of the reflow soldering furnace to ensure that the welding process is carried out under optimal conditions.

3. Improve mounting accuracy: Use high-precision mounting machines for component mounting to ensure accurate placement and angles, and reduce the defect rate during the welding process.

4. Equipment maintenance and calibration: Regular maintenance and upkeep of the reflow welding machine to ensure normal operation of the equipment; Calibrate welding parameters to ensure stable and reliable welding quality.

5. Employee training: Strengthen the quality awareness and skill training of employees, improve their understanding and operational level of reflow soldering technology, and reduce the incidence of errors during the welding process.

6. Environmental control: Keep the welding workshop clean and dry, and avoid the impact of environmental factors such as dust and humidity on welding quality.

7. Testing and screening: Strictly inspect and screen the PCB boards after welding, including visual inspection, functional testing, X-ray inspection, etc., to ensure product quality.

8. Traceability and Improvement: Establish a comprehensive welding process traceability system, analyze and improve welding quality issues, and continuously improve welding quality and reliability.

Through the above efforts, the welding quality and reliability of reflow soldering can be effectively improved, the defect rate can be reduced, and the performance and stability of electronic products can be improved.