How to detect welding quality issues in electronic components using X-ray equipment

Release time:2024-06-24Publisher:Jeenoce

Welding is one of the important links in the manufacturing of electronic products, playing an important role in the assembly process of electronic products. The quality of welding directly determines the quality of the product. Welding technology has a wide range of applications in various industries, especially in electronic product experiments, debugging, and production. Most malfunctions in electronic products are caused by electronic components, mainly due to poor soldering quality of electronic components. Therefore, it is very necessary to use testing equipment to test the welding quality of electronic components.

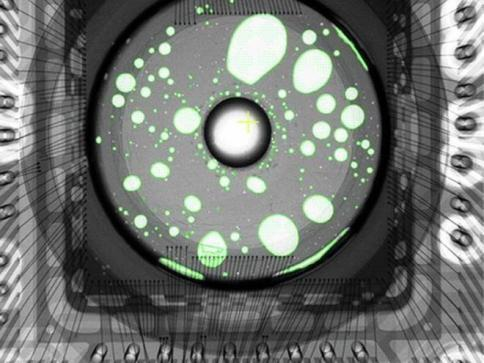

X-ray devices cannot penetrate high-density and thick substances such as tin and lead, which can form dark images. However, X-ray devices can easily penetrate low-density and thin substances such as printed plates and plastic packaging, and will not form images. Based on this phenomenon, the welding quality of electronic components can be judged through images.

Taking BGA components as an example, their solder joint defects mainly include solder bridging, solder bead holes, voids, misalignment, opening, solder ball leakage, welded joint fracture, and virtual soldering. After the BGA device is soldered, there should be no welding bridging between adjacent solder balls. By using X-ray equipment for detection, many small defects that cannot be observed by the naked eye can be found, such as circuit bridging. X-ray can pass through the circuit board and scan images inside the circuit board, achieving 2.5D detection through measurements such as line distance, circle diameter, concentric circles, and distance between points and centers. Using memory programming to automatically record and detect motion paths, accurate positioning, and convenient for small batch repeated detection. Provides a large navigation window, allowing users to click on any area of the tested image with the mouse, automatically and quickly locate the target detection point, and supports multiple image formats. The detected image can be processed in real-time and saved online.