What are the characteristics of high-speed precision dispensing machines? What are the precautions for use?

Release time:2024-06-19Publisher:Jeenoce

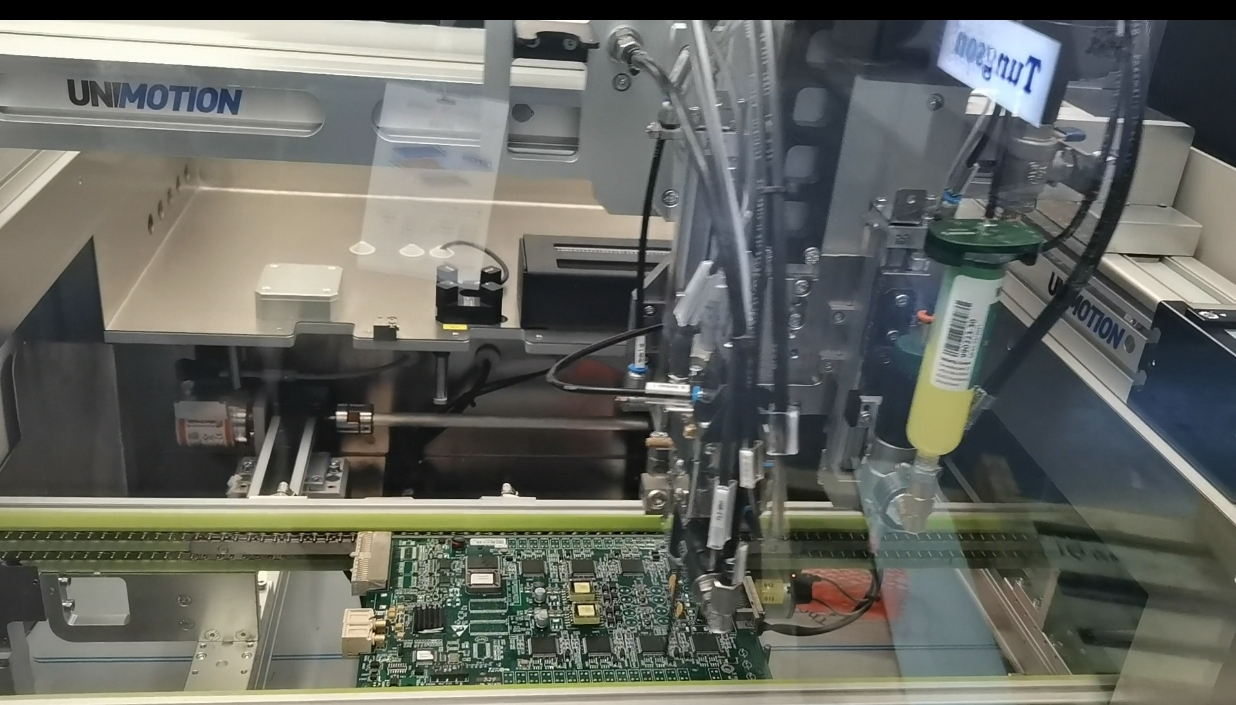

As a new type of dispensing equipment, high-speed precision dispensing machines are also ubiquitous in our production and daily life. Whether it is small or large dispensing machines, they are all precision equipment. During the dispensing process, it is important to pay attention to all operations on the machine and be careful. Today, let's talk about the characteristics of high-speed precision dispensing machines.

1、 The characteristics of high-speed precision dispensing machines

1. Fast speed

Traditional dispensing is slow and requires the use of multiple buttons, requiring manual adjustment of direction. Use multiple buttons to control the amount of glue. Adjust the amount of glue by adjusting the button or applying force on several buttons. This dispensing method will result in a significant speed difference and requires a longer time to complete. And it will affect the quality of the product. Nowadays, most products are glued through manual adjustment buttons.

2. High precision

The high-speed intelligent dispensing system adopts advanced CNC control, greatly improving the accuracy of dispensing equipment. The dispensing system runs smoothly, with a running speed of up to 600-1000r/min. Having high dispensing speed and continuous dispensing can also achieve high quality. This is something that most brands of dispensing machines on the market cannot achieve now. The high-speed stability of the dispensing system not only makes dispensing more reliable and fast, but also enables high-speed and stable operation, thereby improving the production efficiency and product quality of enterprises. A high-quality, high-speed, accurate, and stable dispensing system can improve the quality and efficiency of enterprise products. Therefore, it is necessary to understand how dispensing equipment and other dispensing systems cooperate with high-speed precision dispensing machines to improve dispensing quality and the efficiency and quality of the entire production process.

2、 Precautions for using a high-speed precision dispensing machine

1. Before dispensing, remove the glue from the main unit and clean the dirt on all components of the system.

First, fix the machine in place, and then use an air pump to inject glue into the main machine. The air pump should not leak glue, and the glue should not flow out of the dispensing machine, otherwise it will cause internal blockage of the machine and affect work efficiency. After starting up, turn off the control switch first, and then turn on the power switch. At this time, the motor can run, but it cannot exceed the rated voltage. Then turn off the power switch, turn off the power switch of the air pump, turn off the control switch after the motor stops running, then turn off the power switch, press the "1" button, start dispensing, press the "2" button to reset the glue head, and then reset the control switch; Press the "3" button to reset the control switch.

2. After each dispensing, clean the glue thoroughly and keep the internal system clean and hygienic.

When cleaning the high-speed precision dispensing machine, be careful not to have oil stains. After the equipment is running, the exhaust fan must be turned on to remove moisture and dirt from the air, and then the dust must be cleaned with a vacuum cleaner. If there is abnormal sound during the operation of the equipment, it is because there is a leakage point in its sealing ring or there is a leakage point inside the machine. In this case, timely maintenance or replacement of new components or replacement of new sealing rings should be carried out to solve it. When cleaning, be sure to pay attention to whether there is dust and other debris inside the equipment, especially the dispensing components. At the same time, it is necessary to separate the glue adhered to the adhesive plate. Mix the glue with compressed air and clean the glue dispensing board before proceeding with the dispensing operation.