The importance of solder paste dispensing in electronic product manufacturing

Release time:2024-06-14Publisher:Jeenoce

In the past, our communication methods were not well-developed and could only be communicated through letters. Later on, telegrams, dial-up phones, BB machines, and other products gradually began to emerge. Slowly, the time for information transmission becomes shorter, and it will no longer be possible to receive messages from a few months ago after such a long interval. Or use a computer to write an email, and within a few seconds, the other party will receive it. The reduction in time has clearly shortened by many times, and communication at work has also been greatly facilitated.

Until now, with just one mobile phone in hand, anyone can immediately know where a major event has occurred if there is any disturbance. Technology is becoming more and more advanced, and there are more and more styles of smartphones, which are becoming more and more intelligent. They can even distinguish between those used by young people and those used by the elderly. Do you know how the internal components of smart electronic products are composed? The internal components of electronic products are very complex. Each part has its own function, but it also relies on some special substances to link together and make each part work together. This special substance is solder paste dispensing. In the process of producing electronic products, it is a relatively important and indispensable substance.

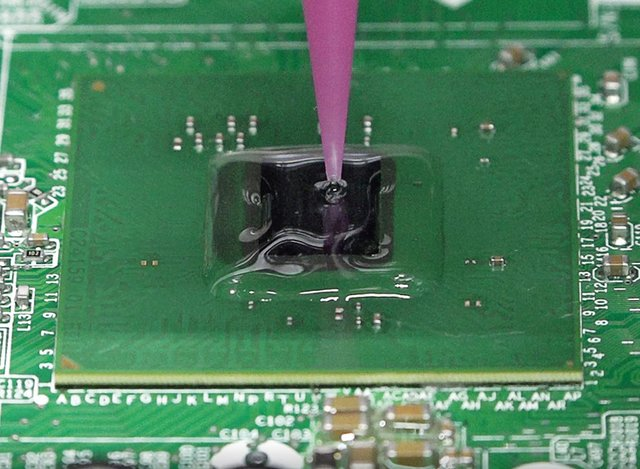

There are three ways to apply solder paste: needle contact, spray, and screw. The circuit operation of each product is different, so it is necessary to use different methods to connect the circuit boards. This material has good sphericity, smooth surface, and good rheological properties. Due to the fact that this substance needs to be coated onto the solder pad through a needle, it is necessary for this material to maintain good fluidity during long-term operation and not cause blockage. In addition, this material needs to be free from drawing or sticking during use, and has a certain degree of shape retention ability.