Structure of nitrogen reflow welding cooling zone

Release time:2024-06-11Publisher:Jeenoce

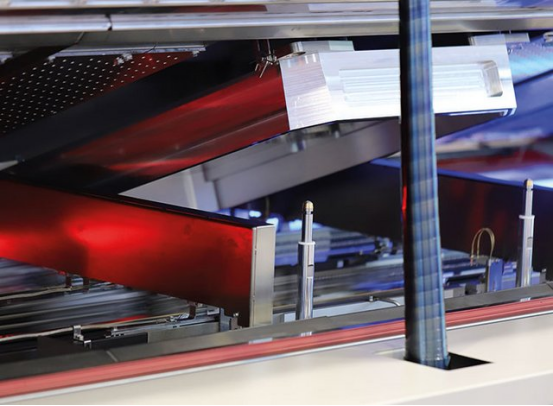

The reflow soldering cooling zone is a specially made cooling module after the reflow zone, connected to an external chiller, which can achieve efficient cooling. Nitrogen reflow soldering adopts dual cooling zone cooling: the gas cooled by heat exchange is applied to the PCB board from above through water-cooled heat exchangers, cooling fans, and air curtains at the outlet.

After reflow soldering, the PCB board must be immediately cooled to achieve good soldering results. Therefore, there is a cooling zone at the end of the reflow soldering furnace. The structure of the nitrogen reflow welding cooling zone is a water circulating heat exchanger. The cooling fan blows hot air into the circulating water heat exchanger, and the cooled gas is then directed onto the PCB board. The heat inside the heat exchanger is carried away by the circulating water, which is cooled and then flows back to the heat exchanger.

Due to the tendency of flux to condense in the cooling system, it is necessary to regularly inspect and clean the flux on the flux filter. Otherwise, the decrease in thermal cycling efficiency will reduce the efficiency of the cooling system, leading to poor cooling and a decrease in the welding quality of the product. The long-term stability of PCB boards with overheated soldering will decrease

Although the cooling zone structure of reflux furnaces from different manufacturers may not be the same, the basic principle is the same. The cooling zone generally has two types of structures: double-sided cooling and single-sided cooling. Single sided cooling refers to the installation of a cooling system only on top of the conveyor belt, while double-sided cooling has cooling systems on both sides of the conveyor belt. Generally speaking, single-sided cooling can meet the cooling needs of ordinary electronic products.