Application of Industrial CT Inspection for Die Castings

Release time:2024-06-05Publisher:Jeenoce

Die castings are a common industrial component commonly used in fields such as automobiles, aerospace, and electronic equipment. Due to its complex internal structure and precise manufacturing process, conventional surface inspection methods often cannot meet the requirements for its internal quality. Therefore, industrial CT inspection technology has become an important quality control method, widely used in the quality inspection of die castings.

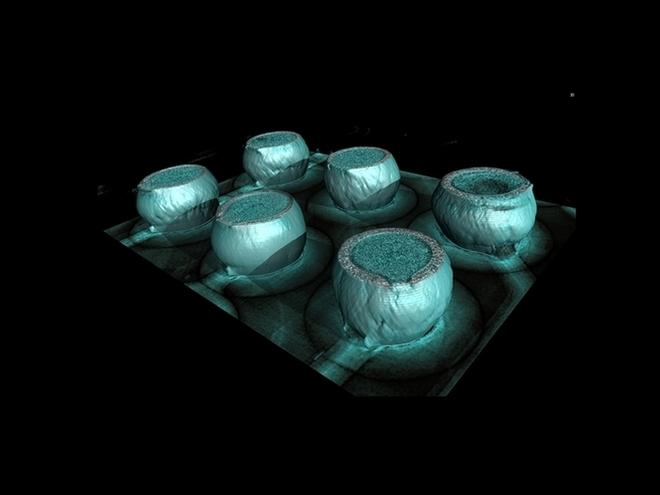

Industrial CT inspection is a non-destructive testing technology based on X-rays, which generates images of the three-dimensional internal structure of the object being tested through 360 degree X-ray scanning, thereby achieving the detection and analysis of internal defects, pores, bubbles, and other defects. For die castings, industrial CT inspection has the following advantages:

Firstly, industrial CT inspection can comprehensively and quickly obtain internal structural information of die castings. Traditional inspection methods often require cutting or destructive testing of die castings, while industrial CT inspection can obtain internal structural information without damaging the sample, greatly improving inspection efficiency and cost-effectiveness.

Secondly, industrial CT inspection can provide accurate quantitative analysis of internal defects in die castings. By processing and analyzing CT images, the size, shape, and position of internal defects in die castings can be accurately measured, providing reliable data support for quality control.

In addition, industrial CT inspection can also achieve digital archiving and traceability of die castings. By digitizing and storing CT images, a quality record of die castings can be established, providing reliable technical support for product quality traceability.

Overall, industrial CT inspection technology has important application value in the quality inspection of die castings, which can help manufacturers improve product quality, reduce production costs, and inject new impetus into the development of the die casting industry. With the continuous progress and improvement of industrial CT inspection technology, it is believed that it will play an increasingly important role in the die-casting industry.