Heating principle of infrared reflow soldering

Release time:2024-06-04Publisher:Jeenoce

Infrared reflow soldering is the heating method of the third-generation reflow soldering, and currently, infrared reflow soldering is mostly used on small-scale reflow soldering. The principle of infrared reflow soldering is that 80% of the thermal energy is usually emitted in the form of electromagnetic waves - infrared radiation. The temperature of the solder joint increases after being irradiated by infrared radiation, thus completing the welding process. The wavelength of infrared is usually between the upper limit of visible light wavelength (0.7-0.8 μ m) and millimeter wave, and its progressive division can be called near-infrared from 0.72-1.5 μ m; 1.5-5.6 μ m is called mid infrared; 5.6-1000 μ m is called far-infrared.

Infrared reflow soldering has a strong infrared radiation ability with a wavelength of 1.5-10 μ m, accounting for about 80-90% of the total infrared energy. The transfer of infrared radiation energy is generally non-contact. The object being irradiated can quickly heat up. The mechanism of infrared reflow soldering heating is that when the vibration frequency of the infrared wavelength is in line with the vibration frequency of the molecules of the object being irradiated by it, the molecules of the object being irradiated by it will resonate, causing intense molecular vibration. The intense vibration of the molecules means that the object is heated up.

Infrared reflow soldering furnaces usually have upper and lower heaters in each temperature zone, and each heater is an excellent infrared radiation body. The objects being welded, such as PCB substrates, organic fluxes in solder paste, and plastic bodies of components, have the ability to absorb infrared radiation. Therefore, when these substances are subjected to thermal radiation from the heater, their molecules undergo intense vibration and quickly heat up to the melting temperature of the solder paste, wetting the soldering area with solder and completing the welding process.

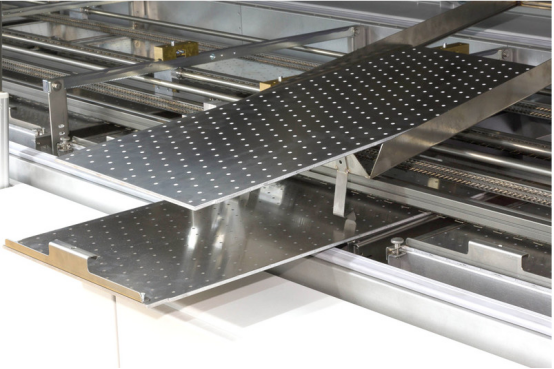

There are many types of infrared reflow soldering heaters, which can be roughly divided into two categories: lamp source radiators, which can directly radiate heat, also known as secondary radiators; Another type is the surface source plate radiator, where the heater is cast into ceramic, aluminum, or stainless steel plates, and heat is transferred to the plate surface through conduction. Two types of heat sources generate radiation with wavelengths of 1-2.5 μ m and 2.5-5 μ m, respectively.