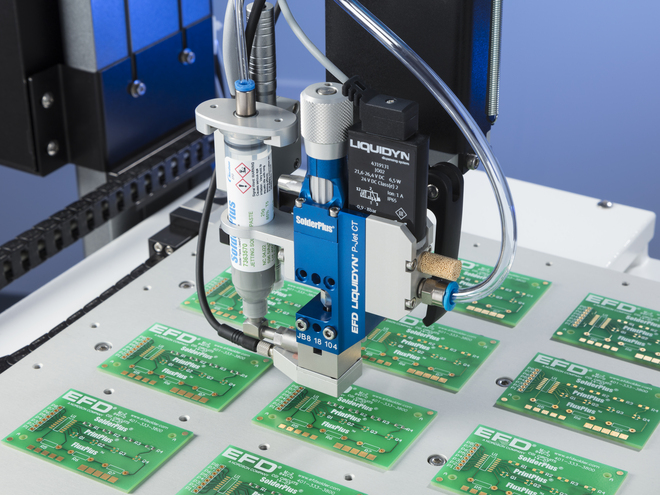

High speed spray dispensing machine helps reduce costs and increase efficiency in production and manufacturing

Release time:2024-06-03Publisher:Jeenoce

High speed spray dispensing machine is an advanced equipment specifically designed for electronic product manufacturing, which has multiple outstanding advantages in dispensing technology. The high-speed spray dispensing machine can achieve automated dispensing in the manufacturing process of electronic products. Due to its high-speed operation and efficient dispensing ability, it can greatly improve the equipment's utilization rate. Automated dispensing can significantly improve production efficiency and reduce production costs while ensuring dispensing quality.

1. Accurate glue quantity control

Through precise liquid control technology, accurate glue amount can be provided at each dispensing position, avoiding glue waste and ensuring product quality and stability. Accurate glue control is crucial for assembly accuracy and reliability in electronic product manufacturing, and the advantage of high-speed spray dispensing equipment makes it a reliable production tool.

2. Advanced visual algorithms

High speed spray dispensing machines are usually equipped with advanced visual algorithms. Through a visual recognition system, they can monitor the shape and position information of the product surface in real time, and achieve accurate dispensing path planning and control. The application of visual algorithms enables dispensing equipment to adapt to various complex product shapes and sizes, improving the accuracy and reliability of dispensing. At the same time, visual feedback can also timely detect problems in production, reducing production downtime and losses caused by product changes or errors.

3. Linear motor driven motion reduces idle running time

Traditional dispensing machines are usually driven by servo motors, while high-speed spray dispensing machines are driven by linear motors, which have higher motion accuracy and response speed. The characteristics of linear motor driven motion systems enable the dispensing head to respond more quickly to changes during movement and reduce motion lag, thereby shortening the idle running time of the equipment. This means that useless time in the production process can be reduced to a greater extent, and production efficiency can be improved.

Compared to other dispensing equipment, high-speed spray dispensing machines have a higher cost-effectiveness. High efficiency and precision have brought significant production cost reduction, and the economic benefits brought by long-term operation are more obvious.