The principle and application of X-ray CT imaging detection technology

Release time:2024-05-30Publisher:Jeenoce

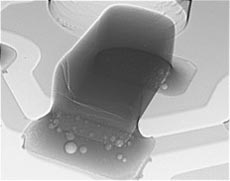

With the increasing demand for welding joint performance in various fields, the detection of welding quality has become increasingly important. Through inspection, defects in the weld seam can be discovered for the improvement of welding technology, and the service process of welded components can be inspected to timely detect defects during use and avoid dangerous behaviors. The current main method is non-destructive testing, X-ray CT imaging detection technology is one of the more successful and advanced, and its application is also quite extensive.

Since its discovery by Roentgen in 1895, X-rays have become an important means of medical diagnosis, radiation therapy, industrial testing, and other fields.

Computed Tomography, CT was born in the 1870s, achieving three-dimensional imaging and eliminating the impact of object overlap on detection. This technology has the characteristics of non-contact, non-destructive, no image overlap, and high resolution, and is recognized as one of the top ten technologies that influenced human development in the 20th century. The X-ray CT imaging system consists of two parts: hardware and software. The hardware part mainly includes the radiation source, detector, and precision machinery of the system; The software part includes CT scanning data acquisition CT image reconstruction and CT image application have three levels, with the core being CT image reconstruction.

CT applications involve many fields such as medicine, industry, biology, petroleum, geophysical exploration, materials, and security inspection. After discovering X-rays, scientists rapidly developed X-ray imaging. Due to its two significant characteristics of short wavelength and strong penetration, X-ray is the best method for high-resolution non-destructive observation of the internal structure of samples, and has been widely used in industry and medicine.