X-RAY non-destructive testing machine effectively detects SMT surface mount processing

Release time:2024-05-29Publisher:Jeenoce

SMT chip mounting refers to a series of process flows for processing on the basis of a PCB. It involves installing surface mounted devices with no or short pins on the surface of a PCB board (printed circuit board) or substrate, and completing circuit assembly technology through reflow soldering or immersion soldering.

The quality of SMT surface mount products has a significant impact on the entire finished product. Currently, in order to eliminate quality differences in the finished product, enterprises will increase production efforts and quality inspection requirements. One of the essential means of product quality control in quality inspection is to detect systematic reasons such as BGA welding quality through testing, so as to better correct or improve measures and prevent the occurrence of batch unqualified products.

Quality inspection methods represented by current non-destructive testing, X-RAY testing bears the brunt, compared to AOI testing ICT testing, X-RAY inspection can better complete internal detection and imaging, while AOI inspection uses appearance inspection, which cannot penetrate the internal structure of the product, thus cannot perform internal perspective on the product, and cannot detect actual defects of the product.

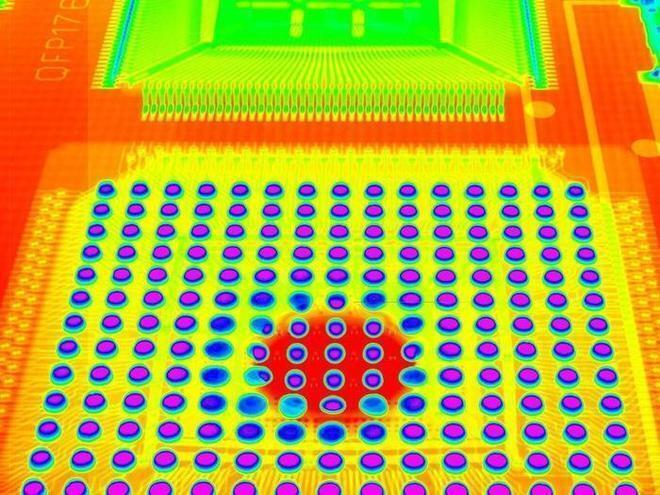

X-RAY, also known as X-ray detector in Chinese, has strong penetrability. Its perspective diagram can display the thickness, shape, and mass density distribution of solder joints, which can fully reflect the welding quality of solder joints, such as open circuits, short circuits, bubbles inside holes, and insufficient tin content. There are two types: direct X-ray detectors and fault profile X-ray detectors. Can be used to detect overall defects, general PCB detection and quality control BGA detection, fine pitch lead and solder joint detection, um level BGA detection, flip chip detection PCB defect analysis and process control, bonding crack detection, microcircuit defect detection, etc., have performed exceptionally well.