How to set the temperature curve for lead-free reflow soldering

Release time:2024-05-28Publisher:Jeenoce

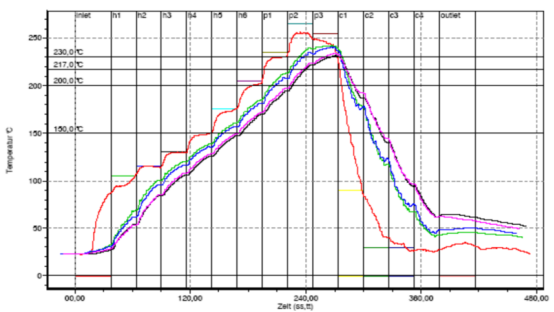

The main manifestation of lead-free reflow soldering process is the reflow temperature curve, and the most important thing is to see how the reflow soldering operator adjusts the temperature of each temperature zone of the lead-free reflow soldering machine to achieve the most perfect curve. The temperature curve of lead-free reflow soldering refers to the curve of the temperature at the test point on the surface assembly device of a PCB changing over time. Therefore, the lead-free reflux temperature curve is an important factor in determining welding defects. The main forms of defects affected by inappropriate reflux curves include: component burst/rupture, warping, tin particles, bridging, virtual soldering, and raw materials PCB delamination and foaming. Therefore, designing the reflux temperature curve appropriately can achieve high yield and reliability. Reasonable control of the reflux temperature curve plays a crucial role in the production process.

For lead-free solder paste, the temperature difference between components must be minimized as much as possible. This can also be achieved by adjusting the reflux curve. Using traditional temperature curves, although the temperature difference between components is inevitable when the board reaches its peak temperature, several methods can be used to reduce it:

1、 Extend the preheating time of reflow soldering. This greatly reduces the temperature difference between components before the peak reflux temperature is formed. Most convection reflux furnaces use this method. However, because the flux may evaporate too quickly through this method, it may cause poor wetting due to oxidation of the pins and pads.

2、 Increase the preheating temperature of reflow soldering. The traditional preheating temperature is generally between 140~160 ° C, which may need to be increased to 170~190 ° C for lead-free soldering. Increasing the preheating temperature reduces the required peak formation temperature, which in turn reduces the temperature difference between components (pads). However, if the flux cannot withstand higher temperature levels, it will evaporate again, causing poor melting humidity due to oxidation of the solder pad pins.

3、 Temperature curve of trapezoidal reflow soldering (extended peak temperature). Extending the peak temperature time of small heat capacity components will allow the components to reach the required reflux temperature with larger heat capacity components, avoiding overheating of smaller components. Using a trapezoidal temperature curve, as shown in Figure 6, a modern combined reflux system can reduce 45mm of BGA and small pin packaging (SOP), The temperature difference between the bodies in the small outline package is 8 ° C.