Eight major defects in reflow soldering and their solutions

Release time:2024-05-27Publisher:Jeenoce

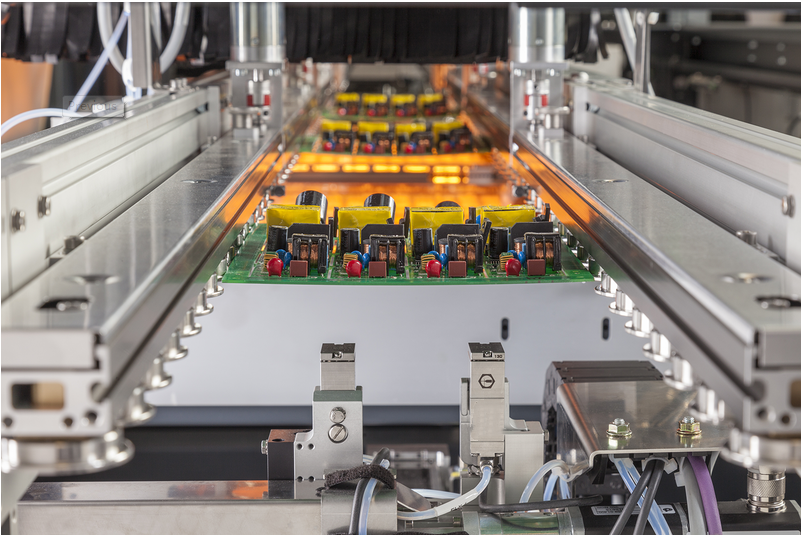

After reflow soldering, electronic product circuit boards often exhibit various defects due to various reasons (reflow soldering equipment, circuit board, worker operation, solder paste, SMT machine, etc.). If these defects are not strictly controlled, they can cause serious problems for the company. Below, JEENOCE will provide a detailed analysis of the eight common defects and propose corresponding preventive solutions. We hope to provide some help to electronic product manufacturers.

1、 Analysis and solution to the problem of solder beads on the circuit board after reflow soldering

1. The mechanism of tin bead formation in reflow soldering

The solder beads (also known as solder balls) that appear in reflow soldering are often hidden between the sides or fine pitch pins of rectangular chip components. During the component placement process, solder paste is placed between the pins and pads of the chip component. As the printed circuit board passes through the reflow soldering furnace, the solder paste melts into liquid. If it is poorly wetted with the pads and device pins, the liquid solder particles cannot aggregate into a solder joint. Part of the liquid solder will flow out of the weld seam, forming tin beads. Therefore, the poor wettability between solder and solder pads and device pins is the fundamental reason for the formation of solder beads.

In the printing process, due to the offset between the template and the solder pad, if the offset is too large, it will cause the solder paste to flow out of the solder pad, making it easy to produce solder beads after heating. The pressure on the Z-axis during the SMT process is an important cause of solder beads, which is often overlooked. Some SMT machines, due to the Z-axis head being positioned based on the thickness of the component, may cause the component to press the solder bud out of the solder pad at the moment it is attached to the PCB. This part of the tin will obviously cause solder beads. In this case, the size of the solder beads produced is slightly larger, and usually it can be prevented by adjusting the Z-axis height again.

2. Cause analysis and control methods

There are many reasons for poor wettability of solder, and the following are the main reasons and solutions related to relevant processes:

(1) Improper setting of reflux temperature curve. The reflow of solder paste is related to temperature and time. If sufficient temperature or time is not reached, the solder paste will not reflow. The temperature rise rate in the preheating zone is too fast and the time is too short, which causes the moisture and solvent inside the solder paste to not completely evaporate. When it reaches the reflow soldering temperature zone, it causes the moisture and solvent to boil and splash out solder beads. Practice has proven that controlling the rate of temperature rise in the preheating zone at 1-4 ℃/S is ideal.

(2) If tin beads always appear in the same position, it is necessary to check the design structure of the metal template. The corrosion accuracy of the template opening size does not meet the requirements, the solder pad size is too large, and the surface material is relatively soft (such as copper templates), which can cause the outer contour of the printed solder paste to be unclear and connected to each other. This situation often occurs when printing solder pads for fine pitch devices, and reflow will inevitably cause a large number of solder beads between the pins. Therefore, suitable template materials and manufacturing processes should be selected based on the different shapes and center distances of solder pad shapes to ensure the quality of solder paste printing.

(3) If the time from SMT to reflow soldering is too long, due to the oxidation of solder particles in the solder paste, the flux will deteriorate and its activity will be reduced, which will cause the solder paste to not reflow and produce solder beads. Choosing a solder paste with a longer working life (usually at least 4 hours) will reduce this impact.

(4) In addition, insufficient cleaning of printed boards with solder paste misprints can result in solder paste residue on the surface and in the air. When attaching components before reflow soldering, the printed solder paste may deform. These are also the reasons for the formation of tin beads. Therefore, it is necessary to accelerate the sense of responsibility of operators and process personnel in the production process, strictly follow the process requirements and operating procedures for production, and strengthen the quality control of the process.

II Analysis and solution to the problem of component monument after reflow soldering

One end of a chip component is soldered onto a solder pad, while the other end is raised, a phenomenon known as Manhattan phenomenon. The main reason for this phenomenon is uneven heating at both ends of the component, and the melting of solder paste occurs sequentially. Uneven heating at both ends of the component can occur in the following situations:

1. The design of component arrangement direction is incorrect. We imagine a reflow soldering limit line that spans across the width of the furnace in the reflow soldering furnace, and once the solder paste passes through it, it will immediately melt. One end of the rectangular component is first limited by reflow soldering, and the solder paste is melted first, completely wetting the metal surface of the component end with liquid surface tension; And the other end did not reach the liquid phase temperature of 183 ℃, and the solder paste did not melt. Only the adhesive force of the solder paste was much smaller than the surface tension of the reflow solder paste, so the component end on the unmelted end stood upright. Therefore, it is necessary to ensure that both ends of the component enter the reflow soldering limit line simultaneously, so that the solder paste on the solder pads at both ends melts simultaneously, forming a balanced liquid surface tension and keeping the component position unchanged.

2. Insufficient preheating of printed circuit components during gas phase welding. Gas phase is the process of using inert liquid vapor to condense on component pins and PCB pads, releasing heat and melting solder paste. Gas phase welding is divided into equilibrium zone and steam zone. In the saturated steam zone, the welding temperature can reach up to 217 ℃. During the production process, we found that if the welded components are not preheated sufficiently and subjected to temperature changes above 100 ℃, the gasification force of gas phase welding is easily reduced

Chip components with packaging dimensions smaller than 1206 float up, resulting in the phenomenon of standing up. We preheated the welded components at a temperature of 145-150 ℃ in a high and low temperature box for about 1-2 minutes, and finally slowly entered the saturated steam zone for welding, eliminating the phenomenon of flaking.

3. The impact of pad design quality. If the size of a pair of solder pads in a chip component is different or asymmetric, it can also cause inconsistent solder paste amount in printing. Small solder pads have a fast temperature response, and the solder paste on them is easy to melt, while large solder pads have the opposite effect. Therefore, when the solder paste on the small solder pads melts, the component is pulled straight and vertical under the surface tension of the solder paste. If the width or gap of the solder pad is too large, it may also cause the phenomenon of chip standing. Strictly following the standard specifications for pad design is a prerequisite for solving this defect.

3、 Analysis and solution of bridging (bonding) problems between components after reflow soldering

Bridging is also one of the common defects in SMT production, which can cause short circuits between components and must be repaired when encountering bridging.

(1) Quality issues with solder paste

The metal content in solder paste is relatively high, especially after a long printing time, which is prone to an increase in metal content; The solder paste has low viscosity and flows out of the solder pad after preheating; Poor slump of solder paste, which flows out of the solder pad after preheating, can cause IC pin bridging.

(2) Printing system

The printing machine has poor repeatability accuracy, uneven alignment, and solder paste is printed outside of copper and platinum, which is more common in fine pitch QFP production; Poor alignment of steel plates and PCBs, as well as incorrect design of steel plate window size/thickness and uneven alloy coating in PCB pad design, can lead to excessive solder paste and cause solder joints. The solution is to adjust the printing machine and improve the coating layer of PCB pads.

(3) Paste and place

Excessive sticking pressure and immersion of solder paste under pressure are common reasons in production, and the Z-axis height should be adjusted. If there is insufficient SMT accuracy, component displacement, and IC pin deformation, improvement should be made based on the cause.

(4) Preheating

The heating rate is too fast, and the solvent in the solder paste cannot evaporate in time.

4、 Analysis and solution of material/core suction problems in components after reflow soldering

Core suction phenomenon, also known as core pulling phenomenon, is one of the common welding defects, commonly seen in vapor phase reflow soldering. Core suction phenomenon refers to the phenomenon of solder detaching from the solder pad along the pins and between the chip body, resulting in serious virtual soldering.

The reason for this is usually believed to be the high thermal conductivity of the original pins, which causes rapid heating, resulting in the solder preferentially wetting the pins. The wetting force between the solder and the pins is much greater than that between the solder and the pads, and the upward warping of the pins will further exacerbate the occurrence of core suction phenomenon. In infrared reflow soldering, The organic solder flux in PCB substrate and solder is an excellent absorbing medium for infrared radiation, while the pins can partially reflect infrared radiation. In comparison, solder preferentially melts, and its wetting force with the solder pad is greater than that between it and the pins. Therefore, the solder part will rise along the pins, reducing the probability of core suction phenomenon.

The solution is: during vapor phase reflow soldering, the SMA should be fully preheated before being placed in the vapor phase furnace; Careful inspection and assurance of the solderability of PCB pads should be carried out, and PCBs with poor solderability should not be used in production; The coplanarity of components cannot be ignored, and devices with poor coplanarity should not be used in production.

V Analysis and solution to the problem of blistering of solder mask on printed boards after reflow soldering

After welding, printed circuit board components may have light green bubbles around individual solder joints, and in severe cases, bubble shaped objects the size of fingernails may appear. This not only affects the appearance quality, but in severe cases, it can also affect performance, making it one of the common problems in welding processes.

The fundamental reason for the blistering of the solder mask is the presence of gas/water vapor between the solder mask and the anode substrate. Trace amounts of gas/water vapor can be carried into different processes, and when encountering high temperatures, gas expansion leads to delamination between the solder mask and the anode substrate. During welding, the temperature of the solder pad is relatively high, so bubbles first appear around the solder pad.

Nowadays, the processing process often requires cleaning and drying before proceeding to the next step. For example, after etching, it should be dried before applying a solder mask. If the drying temperature is not enough, water vapor will be carried into the next step. Poor storage environment before PCB processing, high humidity, and lack of timely drying treatment during welding; In the wave soldering process, water-based solder resist is often used. If the PCB preheating temperature is not enough, the water vapor in the flux will enter the interior of the PCB substrate along the hole wall of the through-hole, and the water vapor will first enter around the solder pad. When encountering high welding temperatures, these situations will produce bubbles.

The solution is:

(1) Strict control should be exercised over all aspects, and purchased PCBs should be inspected and stored. Under standard circumstances, there should be no bubbles.

(2) PCB should be stored in a ventilated and dry environment, with a storage period not exceeding 6 months;

(3) PCB should be pre baked in an oven at 105 ℃/4H~6H before welding;

6、 Analysis and solution of PCB distortion problem after reflow soldering

PCB distortion is a common problem in SMT production. It will have a significant impact on assembly and testing, so it should be avoided as much as possible in production, There are several reasons for PCB distortion:;

(1) Improper selection of raw materials for PCB itself, The Tg of PCBs is low, especially for paper-based PCBs. If the processing temperature is too high, it can cause the PCB to bend.

(2) Unreasonable PCB design and uneven distribution of components can cause excessive thermal stress on the PCB, and larger connectors and sockets can also affect the expansion and contraction of the PCB, and even permanent distortion.

(3) Double sided PCB, if the copper foil on one side is left too large (such as ground wire). If there is too little copper foil on the other side, it will cause uneven shrinkage and deformation on both sides.

(4) Excessive temperature during reflow soldering can also cause distortion of the PCB.

The solutions for the above reasons are as follows:

When price and space allow, choose a PCB with a higher Tg or increase the thickness of the PCB to achieve the best aspect ratio; Reasonable design of the copper foil area on both sides of the PCB should be balanced, covered with steel layers in areas without circuits, and appear in a network form to increase the stiffness of the PCB. Preheating the PCB before SMT should be carried out under the condition of 105 ℃/4H; Adjust the fixture or clamping distance to ensure the space for PCB thermal expansion; Lower the welding process temperature as much as possible; When mild distortion has already occurred, it can be placed in the positioning fixture, heated and reset to release stress, and generally satisfactory results will be achieved.

7、 Analysis and solution to the problem of open circuit/virtual soldering of IC pins after reflow soldering

Partial soldering of IC pins after soldering is a common welding defect, which can be caused by many reasons. The main reason is poor coplanarity, especially in QFP devices. Due to improper storage, the pins are deformed and sometimes difficult to detect (some SMT machines do not have coplanar functionality). Therefore, attention should be paid to the storage of the components, and do not take the components or open the packaging casually. The second issue is poor solderability of the pins. Long storage time of ICs, yellowing of pins, and poor solderability can also cause virtual soldering. During production, the solderability of components should be checked, and special attention should be paid to the storage period not being too long (within one year from the manufacturing date). When storing, they should not be exposed to high temperature and humidity, and packaging bags should not be opened casually. The third reason is poor quality of solder paste, low metal content, and poor solderability. The metal content of solder paste commonly used for QFP devices should not be less than 90%. The fourth reason is that the preheating temperature is too high, which can easily cause oxidation of IC pins and deteriorate solderability. The fifth reason is that the template window size is small, resulting in insufficient solder paste. Usually, after template manufacturing, the window size of the template should be carefully checked, which should not be too large or too small, and attention should be paid to matching the PCB pad size.

8、 Analysis and solution of cracking problem in chip components after reflow soldering

In SMC production, cracking of chip components is common in multi-layer chip capacitors (MLCC), mainly caused by effect forces and mechanical stresses.

(1) For MLCC type capacitors, there is significant structural fragility. Typically, MLCC is composed of multiple layers of ceramic capacitors stacked together, with low strength and extreme resistance to thermal and mechanical impact.

(2) During the SMT process, the suction and discharge height of the Z-axis of the SMT machine, especially for some SMT machines that do not have Z-axis soft landing function, is determined by the thickness of the chip components rather than pressure sensors. Therefore, the tolerance of component thickness can cause cracking.

(3) The bending stress of PCB, especially after welding, can easily cause cracking of components.

(4) Some assembled PCBs may damage components during segmentation.

The preventive measure is to carefully adjust the welding process curve, especially the preheating zone temperature should not be too low; When mounting, the suction and discharge height of the Z-axis of the mounting machine should be carefully adjusted; The warpage of PCBs, especially after welding, should be corrected accordingly. If there are quality issues with the PCB board, special attention should be paid.

The reflow soldering defects of electronic products are divided into main defects, secondary defects, and surface defects. Any defect that renders the SMA function of electronic products ineffective is called the main defect; Minor defects refer to defects where the wetting between solder joints is still good and will not cause the loss of SMA function in electronic products, but may affect the product's lifespan; Surface defects refer to those that do not affect the functionality and lifespan of the product. We are well aware that reasonable surface assembly technology plays a crucial role in controlling and improving the quality of SMT products during our research and production of SMT processes. The above eight phenomena are common adverse phenomena, and there are other defects that may not affect the SMA function of electronic products that I have not listed one by one. Some of them also require careful observation and analysis by everyone. I believe that with care, everything can be solved. If there are still uncertainties, please contact JEENOCE for detailed analysis.