How to choose reflow soldering equipment?

Release time:2024-05-21Publisher:Jeenoce

Many manufacturers do not know how to choose the most suitable reflow soldering equipment when purchasing. Generally speaking, reflow soldering in areas 8 to 10 is most commonly used in mass production. In our experience, some products are more cost-effective when using temperature zones 4 to 6. It can meet the reflow specifications of solder paste manufacturers and provide reliable and high-quality welding performance. So how can you determine how many products can be processed by reflow soldering in zones 4, 5, or 6? We provide you with a reference based on data from both solder paste and equipment.

1. The width of the conveyor belt must meet the maximum PCB size requirements

Based on your PCB, choose the ribbon width: For PCB200MM ribbon applications, choose 300MM. Generally, for 300, 350, 400, 450, 500, and 600MM, the wider the ribbon width, the higher the reflow soldering power. Therefore, choosing the appropriate one is the most important.

2. Heating time of solder paste

The temperature of the reflow soldering equipment should follow the requirements of the solder paste. Solder paste manufacturers usually provide a relatively wide window time for each stage of the reflow curve: preheating and constant temperature time of 120 to 240 seconds, reflow time of 60 to 120 seconds/liquid above time. We found that the average total heating time is 4 to 4 ½ The minute (240-270 seconds) is a good and relatively conservative estimate. For this simple calculation, we suggest that you ignore the cooling process of the welded profile. Cooling is important, but it usually does not affect the welding quality unless the PCB cools too quickly.

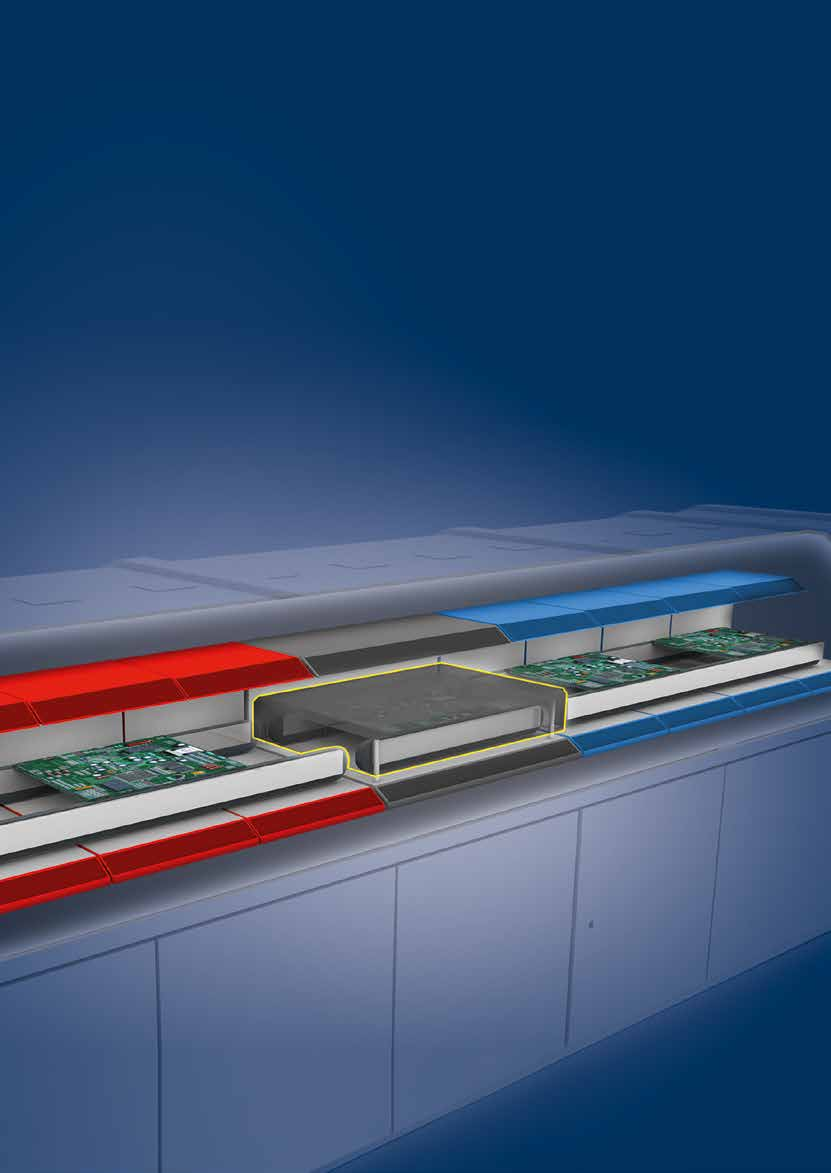

3. The length and number of heating zones

The longer the length of the heating zone and the more heating zones there are, the easier it is to adjust and control the temperature curve. Generally, for medium and small batch production, 5-6 temperature zones are selected, and a reflux furnace with a heating zone length of about 1.8m can meet the requirements. In addition, the upper and lower heaters should be independently temperature controlled to adjust and control the temperature curve.

4. Maximum number of reflux plates

Assuming that you have to load boards end-to-end on the conveyor of the reflow soldering equipment at maximum capacity, it is easy to calculate the maximum output. For example, if your circuit board is 7 inches long and the speed range of the 6-zone reflow soldering furnace is 17.9 inches to 20.2 inches per minute, the maximum throughput of the reflow soldering is 2.6 to 2.9 circuit boards per minute. That is to say, the upper and lower circuit boards will be soldered in about 20 seconds.

5. What other factors have an impact on reflow soldering equipment

In addition to the above factors, there are many other factors that need to be considered. For example, both double-sided panels and manual assembly operations can affect the efficiency of reflow soldering. Choose appropriate reflow soldering equipment based on the actual situation of your own factory and the output of other processes.