Glue dispensing valve: a key component of precision glue control

Release time:2024-05-15Publisher:Jeenoce

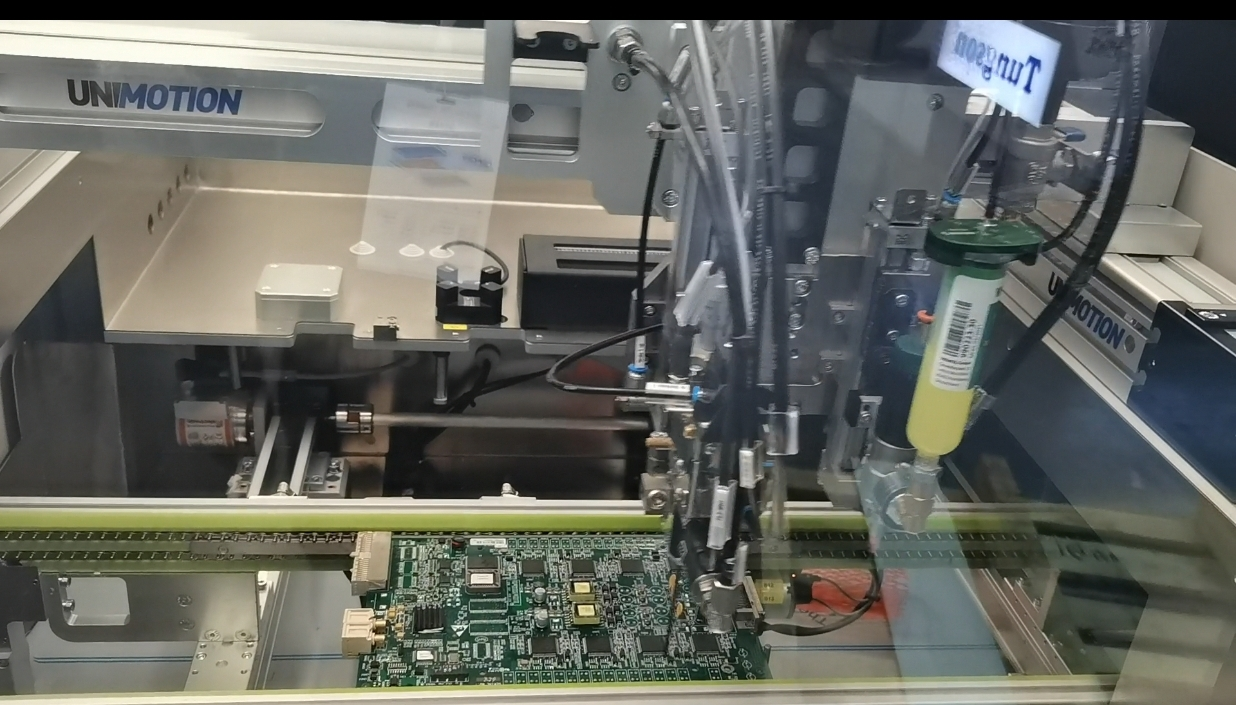

As a key component of the glue dispensing system, the dispensing valve plays a crucial role in industrial production. It is responsible for controlling the flow rate and spraying method of glue, achieving relatively accurate glue spraying, filling, and packaging. The performance and accuracy of the dispensing valve directly affect product quality and production efficiency. It can accurately control the flow of glue and achieve accurate spraying of glue.

Different products and applications require different amounts of glue and spraying methods. It can adjust the flow rate of glue according to needs and control the spraying speed and shape of glue. Whether it is small line dispensing or complex pattern dispensing, it can achieve relatively accurate control, ensure uniform spraying of glue, and improve the appearance quality and consistency of the product.

In addition, its corrosion resistance and wear resistance are also important characteristics. In industrial production, the composition and properties of glue are different. Some glues are corrosive, while others contain particulate matter. It can select appropriate materials and coatings, improve the corrosion and wear resistance of the valve body, extend the service life of the valve, and reduce the frequency of maintenance and replacement.

The dispensing valve is adjustable and replaceable. Different products and process requirements may require different glue flow rates and spraying methods, which can meet different needs by adjusting the internal structure and parameters of the valve body. In addition, it usually adopts a modular design for easy replacement and maintenance. When it is necessary to change the adhesive type or perform valve body maintenance, simply replace the corresponding module or component without replacing the entire part, saving time and cost.

In industrial production, its application is very extensive. It is widely used in fields such as electronic manufacturing, automotive manufacturing, aerospace, medical devices, etc. For example, in electronic manufacturing, it is used in processes such as PCB assembly, chip packaging, and electronic component fixation. In automobile manufacturing, it is used for body sealing, lamp fixation, and assembly processes. In aerospace and medical device manufacturing, it is applied in precision assembly and sealing processes. It ensures the quality and reliability of these key products through precise glue control.

As the core component of the glue dispensing system, the dispensing valve plays a crucial role in industrial production. By controlling and adjusting the glue, it achieves relatively accurate spraying and filling of glue, providing reliable guarantees for product quality and production efficiency. Enterprises should attach importance to the selection, training, and maintenance of this component to fully leverage its advantages and improve product quality and production efficiency. Meanwhile, with the continuous development of technology, we can look forward to its further innovation and application in various fields, bringing more possibilities to industrial production.