X-ray detection of welding defects in LED chip packaging process

Release time:2024-05-13Publisher:Jeenoce

Light Emitting Diode (LED) is a type of semiconductor light-emitting device. LED has many advantages such as long service life, low power consumption, and environmental protection, and has been widely used in the field of indication and display. With the continuous improvement of high-power white LED output rate, LED lighting has become possible, and therefore, LED is also known as the "fourth generation lighting source". In China, due to the dual limitations of equipment and production, most manufacturers use manual welding methods, and the proportion of defective products caused by unqualified welding systems during the packaging process accounts for more than 40%. Therefore, it is necessary to inspect the welding quality during the LED packaging process.

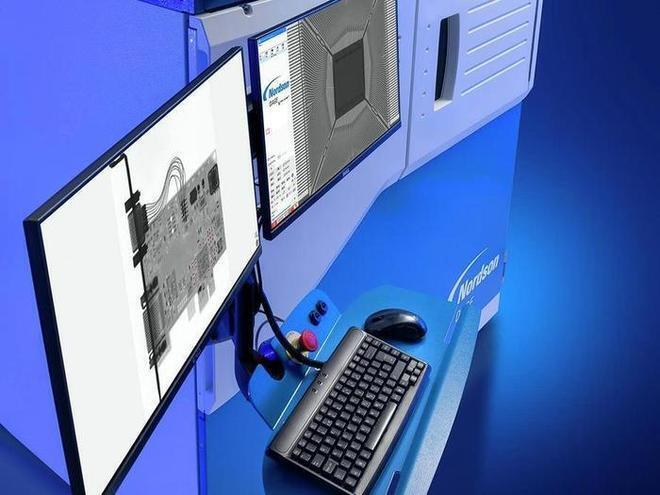

There are various defects in the packaging process of LED chips, including contamination welding, repeated welding, solder joint damage and deformation, and inappropriate welding lead wire angles. They are mainly caused by lax production process control, welding points not being welded in effective areas, and low cleanliness of the production environment. These welding defects may lead to an increase in contact resistance, a decrease in welding firmness, and even cause short circuits between the positive and negative electrodes, thereby reducing the reliability of the components. The method of X-ray testing not only does not damage the structure of the components themselves, but also displays solder joint defects very intuitively and clearly. The testing process is simple and the results are obvious.