Application of high-precision solder paste dispensing

Release time:2024-05-11Publisher:Jeenoce

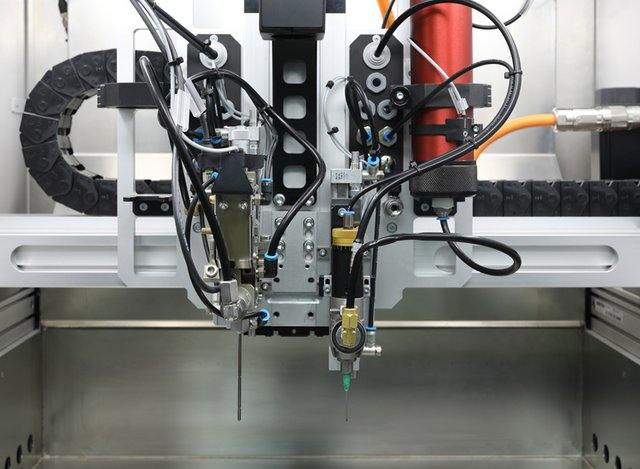

With the increasing development of electronic products and the increasing demand for diversification, the application of high-precision solder paste dispensing is very extensive, and this technology plays an important role in the field of electronic manufacturing. It is a method that can accurately control the position and amount of solder paste application, suitable for the manufacturing of micro packages, high-density circuit boards, and microelectronic devices. It achieves accurate spraying and distribution of solder paste by using highly accurate dispensing equipment and dispensing needles.

The following are the application scenarios for high-precision solder paste dispensing:

1. Micro packaging components: On small-sized packaging components such as chips, sensors, and micro motors, it can achieve accurate welding and connection. By controlling the dispensing position and amount of solder paste, the accuracy and reliability of solder joints are ensured, and the quality and performance of products are improved.

2. High density circuit boards: Modern circuit board designs tend to have smaller and more compact layouts, requiring higher accuracy and consistency of solder joints. It can achieve accurate application of small solder joints on high-density circuit boards, reduce welding deviations and the risk of short circuits, and improve the reliability and performance of circuit boards.

3. Fine electronic devices: Many fine electronic devices, such as flexible electronics, LED packaging, and MEMS devices, have very high requirements for the accuracy of solder paste dispensing. Its technology can achieve small and accurate dispensing operations, ensuring the stability and reliability of the device.

The high-precision solder paste dispensing technology brings multiple advantages, including:

1. Accurate control: By using accurate dispensing equipment and needles, the accuracy of solder paste can be controlled, ensuring consistency in the application position and amount, and improving the repeatability of the process.

2. Efficient production: High precision solder paste dispensing technology can achieve high-speed dispensing and improve production efficiency. Its fast and accurate dispensing operation can greatly reduce the production cycle and improve the throughput of the production line.

3. Support for complex design: With the complexity and diversification of electronic products, the requirements for dispensing are also increasing. High precision solder paste dispensing technology can adapt to complex circuit board layouts and small packaging components, supporting fine and complex design requirements.

In summary, the application of high-precision solder paste dispensing technology is very extensive. It improves the accuracy and reliability of solder joints by accurately controlling the application position and amount of solder paste, promoting the quality and performance improvement of electronic products. However, in the application process, attention should be paid to technical details and parameter control to ensure the stability and consistency of the dispensing process. With the continuous development and innovation of technology, this technology will continue to promote the accuracy and efficiency improvement of electronic manufacturing processes.