Application of X-RAY detection equipment in PCB defect detection

Release time:2024-05-06Publisher:Jeenoce

In recent years, with the development of industries such as communication, computer, and consumer electronics, the printed circuit board (PCB) industry has also rapidly developed. According to data statistics, the global output value of PCBs accounts for approximately 18% of the total output value of electronic components. In 2001, the global output value of PCBs reached 46 billion US dollars. In recent years, the PCB industry in China has developed rapidly. In 2003, the output value of printed circuit boards in China was 50.1 billion yuan, a year-on-year increase of 32.40%, surpassing the United States and ranking second in the world. In 2005, China's PCB production value exceeded 86.8 billion yuan, and in 2006, it surpassed Japan, ranking first in the world in both output value and output, becoming a true major producer of PCB industry.

Printed Circuit Board (PCB), as one of the most fundamental and active industries in the electronic industry, has developed rapidly. With the increasing development of semiconductor design and manufacturing technology, printed circuit boards are also moving towards ultra-thin, high-density, multi-layer, high-performance and other discoveries. At present, the design and processing level of printed circuit boards has reached 0.2-0.3mm (aperture), 0.15-0.12mm (line width and spacing), and the number of layers has reached 46 (Fuji Corporation) or even more. It can be said that the high-tech and high complexity of printed circuit boards have reached a relatively high level. However, while achieving rapid development, the PCB industry is also facing huge challenges

The challenge is the quality issue of PCBs. The current quality situation of printed circuit boards is not optimistic, because the quality of printed circuit boards depends on the quality of each line and hole on the board. Quality problems such as being too thin, too thick, incomplete, sticky, disconnected, or misaligned in thousands of lines and holes on a board can affect the final product quality or lead to waste. The more layers a circuit board has, the more prominent the problem becomes, resulting in a higher scrap rate.

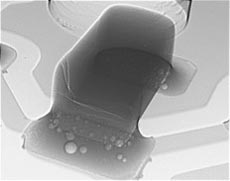

Due to the influence of many uncertain factors such as raw materials, equipment stability, temperature, environment, and human errors during the production process of circuit boards, defects are difficult to avoid. Therefore, an efficient, high-speed, and high-precision automatic defect detection equipment for printed circuit boards has become an urgent need in the PCB industry. To solve this problem, the technical workers in the factory have come up with various methods: manual inspection, AOI circuit board virtual soldering inspection, electromagnetic vibration circuit board virtual soldering inspection, but the results are not satisfactory. Conventional testing and measurement techniques often only provide surface information of the product, making it difficult to provide complete internal information. X-ray detection technology, as an emerging process method and analytical tool, can detect invisible defects without damaging the product, reflect the internal information of the product, and qualitatively and quantitatively analyze the detection results to detect faults early and reduce the scrap rate.