X-RAY detection technology in the field of PCB assembly

Release time:2024-04-29Publisher:Jeenoce

The rapid development of high-density packaging technology has also posed new challenges to testing technology. In order to cope with challenges, new testing technologies are constantly emerging. X-ray detection technology is one of them, which can effectively control the welding and assembly quality of BGA. Nowadays, X-ray detection systems are not only used for laboratory failure analysis, but have been specifically designed for PCB assembly and semiconductor industry in production environments, providing high-resolution X-ray systems. The principle and application of X-ray detection technology are introduced, and it is pointed out that X-ray detection technology is a necessary means to ensure the quality of electronic assembly.

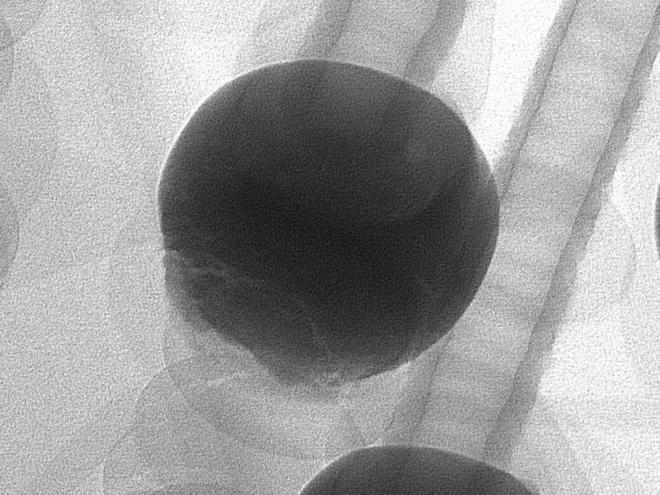

Nowadays, the use of X-rays, such as BGA, Flip chip, and CSP, is becoming increasingly common. In order to ensure the welding quality of invisible solder joints in the PCB assembly process of such devices, X-ray detection equipment is becoming an indispensable and important detection tool. The main reason is that it can penetrate the interior of the package and directly check the quality of the solder joints; Due to the increasing miniaturization of packaging methods for semiconductor components, it is necessary to consider both current and future trends in component miniaturization when examining X-ray detection systems. Therefore, the most suitable X-ray detection system must have clear X-ray images and provide the necessary information for analyzing defects. To achieve this goal, the X-ray detection system must have sufficient magnification to meet current and future needs.

Detection principle

All X-ray detection equipment, whether it is a two-dimensional or three-dimensional system, is basically based on an X-ray projection microscope. The X-ray emission tube generates X-rays through the test sample (such as PCB), which have different absorption rates for X-rays based on the density and atomic weight of the sample material itself, and projects them onto the image receiver. The higher the density of the material, the deeper the shadow, and the closer it is to the X-ray tube, the larger the shadow. Conversely, the smaller the shadow, which is the principle of geometric magnification.

Detection characteristics

All X-ray detection devices, whether two-dimensional or three-dimensional, have the following characteristics

(1) There is an X-ray tube in the equipment that produces X-rays.

(2) A template operating platform can move the template to detect different parts of the template, adjust the magnification, and observe the tilt angle.

(3) An image receiving device can capture X-rays passing through the template and convert them into a good image that can be presented to the user's eyes.